One of the industries that faces high pressure to reduce carbon emissions is construction. The materials at the heart of construction—concrete and steel—are essential but carbon-intensive. Together, they contribute to approximately 13% of global CO₂ emissions.

In response, Carbon Direct and Microsoft have launched a unique guide. It’s called Criteria for High-Quality Environmental Attribute Certificates (EACs) in the Concrete and Steel Sectors. This guide helps companies reduce supply chain emissions. It also speeds up the decarbonization of built environments by tackling its significant emission source: embodied carbon.

The Problem with Embodied Carbon

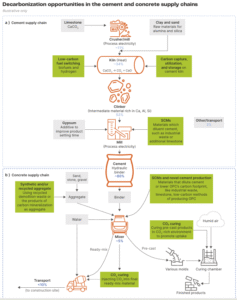

Embodied carbon is different from emissions from energy use. It refers to emissions released when producing and transporting building materials. Concrete and steel are two of the biggest contributors to this problem.

Many companies aim to cut their supply chain emissions. However, tools and systems for this are still being developed, especially for concrete and steel. This is where Microsoft and Carbon Direct’s partnership comes in.

Environmental Attribute Certificates: A Flexible Solution

Environmental Attribute Certificates (EACs) offer a promising way forward. EACs work like Renewable Energy Certificates (RECs). Companies can still enjoy the environmental perks of low-carbon concrete and steel, even if they don’t use them in their supply chain. This flexibility helps companies with complex or global construction projects. They often can’t source green materials directly.

The new guide from Carbon Direct and Microsoft outlines how EACs can be used as a credible tool to bridge this gap. It uses strict criteria to make sure EACs cut emissions for real. This way, they won’t just move emissions around but will help lower carbon emissions in production.

The report is designed to support procurement teams, sustainability officers, and material suppliers in navigating the emerging EAC market with climate integrity.

What Makes an EAC High-Quality?

For an EAC to drive meaningful decarbonization, it must meet specific standards. The guide identifies several critical quality criteria:

-

Additionality:

EACs must represent real emissions reductions that go beyond business-as-usual. The projects should not already be financially viable without the EAC revenue. -

Catalytic Impact:

EACs should promote systemic change by encouraging broader market shifts, technological innovation, or policy adoption that accelerate decarbonization in concrete and steel. -

Procurement Flexibility:

EACs are designed to decouple environmental benefits from the physical material, enabling companies to support low-carbon production even when direct procurement isn’t feasible. -

Quantifiable and Verifiable:

Emissions reductions must be measurable and verified through transparent, third-party processes. Reporting frameworks should follow established methodologies. -

Robust Safeguards:

Projects issuing EACs must meet environmental and social safeguards, avoiding harm to local communities, ecosystems, or other sustainability criteria. -

No Leakage or Double Counting:

EAC systems must prevent double claims or emissions leakage, ensuring that claimed reductions are unique and not offset by emissions elsewhere.

These criteria help build trust in carbon markets. This is important as worries about greenwashing and double-counting emissions claims increase.

For the sector-specific requirements, the guide specifically identified:

Growing Demand for Low-Carbon Materials

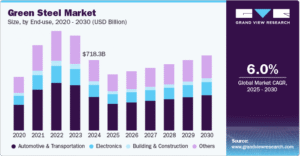

Market trends signal a growing appetite for decarbonized materials. A 2024 report from McKinsey & Company says green steel demand might hit 50 million metric tons a year by 2030. This would be 10–15% of all steel demand.

In another estimation by Grand View Research, the green steel market could grow at 6% from 2025 to 2030.

Similarly, low-carbon concrete markets could grow 13% each year until 2032, says Transparency Market Research.

Regulatory pressure is also playing a role. The U.S. government’s Buy Clean initiative and the Inflation Reduction Act help buy low-carbon construction materials. In Europe, the Green Deal Industrial Plan promotes sustainable construction and materials innovation. These policies drive demand and set clear expectations for transparency. So, verified tools like EACs are now more important than ever.

Microsoft Walks the Green Talk

Microsoft’s involvement reflects its broader climate commitments. As part of its pledge to become carbon negative by 2030, the company is taking a supply chain-first approach. It has invested in carbon removal.

Now, the tech giant views EACs as a way to cut Scope 3 emissions. These emissions come from suppliers and purchased goods, like construction materials.

Julia Fidler, Fuel and Materials Decarbonization Lead, Microsoft, stated:

“EACs have the potential to address a number of the most critical challenges to scaling deep decarbonization solutions, not least by providing financial certainty. By setting a high bar for EACs, we’re ensuring that our investments drive real, additional, and scalable emissions reductions as we invite the industry to join us in shaping a credible, high-impact market for low-carbon building materials.”

Microsoft’s partnership with Carbon Direct shows how companies can take real steps to decarbonize. The new guide serves as a model for measurable action. Their joint efforts aim to reduce emissions, wanting to create a market for environmental integrity in material procurement.

Toward a Climate-Aligned Materials Market

While still in its early stages, the market for EACs in concrete and steel could mature rapidly. The guide is released as investors and regulators push companies to show and cut emissions throughout their value chains.

Emissions from buildings and infrastructure keep increasing, and concrete and steel are tough to decarbonize. Tools like Environmental Attribute Certificates can help the industry build in a climate-friendly way.

Carbon Direct and Microsoft’s new guide defines high-quality EACs. It shows how to use them for real, measurable decarbonization that can allow companies to match their buying power to their climate goals.

The post Building Cleaner: Microsoft and Carbon Direct Launch EAC Guide for Concrete and Steel appeared first on Carbon Credits.