Atmos Zero: The Startup Electrifying Industrial Steam and Redefining Clean Manufacturing

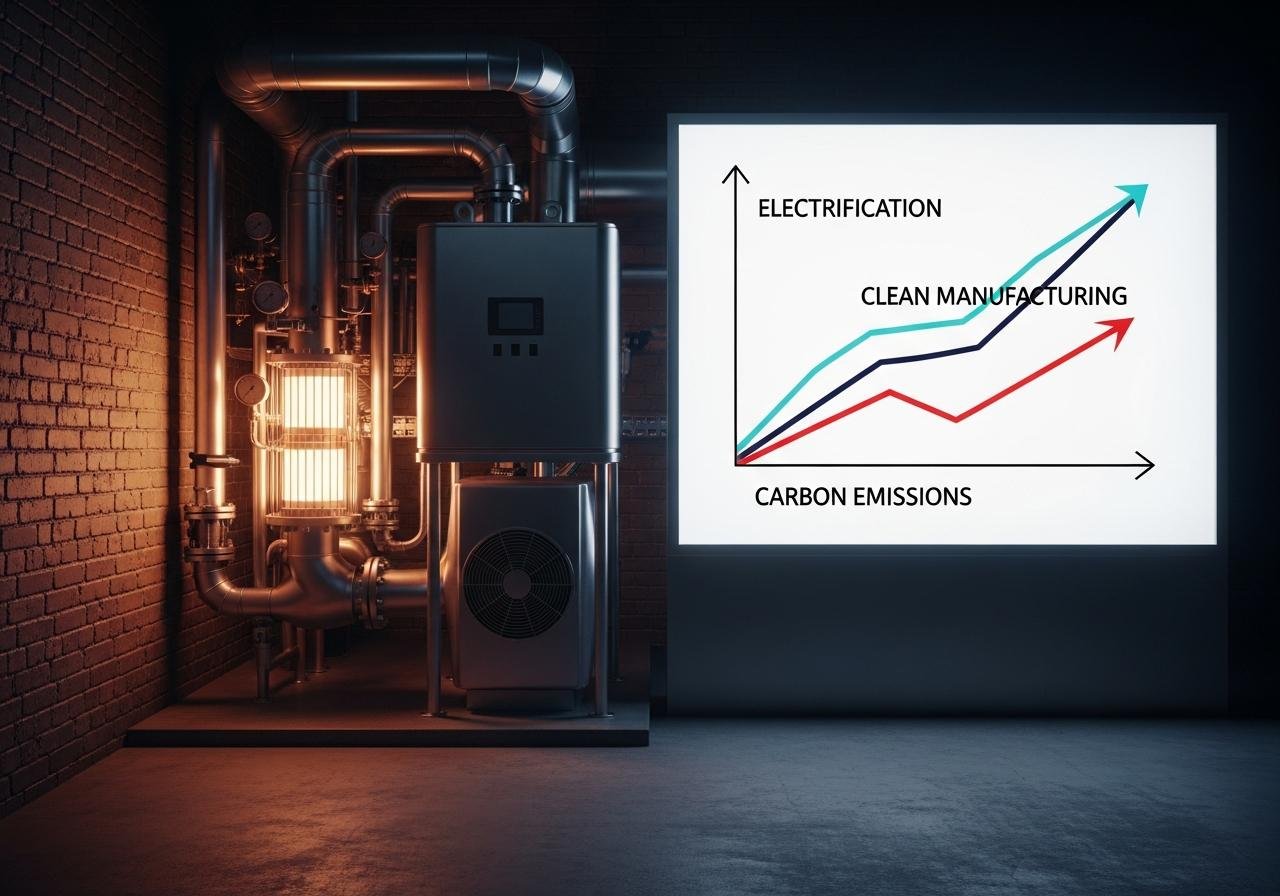

When most people think about electrification, they picture cars, homes, and gadgets running on clean electricity. But there’s a less visible player behind every manufactured good — industrial steam. From brewing beer to making chemicals, steam is the lifeblood of factories worldwide. And until recently, producing it without burning fossil fuels was considered nearly impossible. That’s changing fast, thanks to a Colorado-based startup called Atmos Zero.

In less than four years, Atmos Zero has achieved what the industrial sector has struggled with for over a century: generating high-temperature steam using a heat pump instead of combustion. The innovation could reshape heavy industry’s carbon footprint, one steam boiler at a time.

The Steam Problem Nobody Talks About

Industry accounts for around 30% of global energy use and about a third of total U.S. energy consumption. And much of that energy goes toward generating heat. In fact, three-quarters of industrial emissions come from heat-related processes — and roughly half of that heat is delivered as steam (explore more on sustainable practices to maintain health and wellness here). From food sterilization and brewing to pharmaceuticals and district heating, steam keeps the global economy humming.

Yet, while we talk about electric vehicles and rooftop solar, industrial heat remains largely overlooked. Conventional boilers rely on natural gas, oil, or coal to generate steam at high temperatures and pressures. The basic technology hasn’t changed much since the 19th century, when Babcock and Wilcox patented the modern steam boiler in 1867. That legacy system remains efficient enough to persist — until now.

How Atmos Zero Reimagined Industrial Steam

Founded in 2021, Atmos Zero set out to create a zero-emissions alternative to the industrial boiler. Just 14 months after launching, the company had built and tested its first commercial-scale heat pump boiler. By mid-2023, they installed a 650-kilowatt pilot system at New Belgium Brewing Company’s flagship brewery in Fort Collins, Colorado.

This wasn’t a lab test. The system has been supplying roughly one-third of New Belgium’s process steam needs — a significant portion for such a demanding operation. Encouraged by the results, the brewer plans to phase out all combustion-based boilers across its facilities in Colorado, Virginia, North Carolina, and Michigan, slashing over half of its operational emissions (learn more on how zero waste living can contribute to similar goals here).

Atmos Zero’s rapid progress has attracted serious attention. The company has raised $28.5 million from top-tier investors like Engine Ventures, 2050 VC, and Constellation Technology Ventures. In 2024, it opened a 100,000-square-foot manufacturing plant in Colorado, with plans to produce hundreds of units per year by 2026. For the hardware-heavy clean tech world, that’s lightning speed.

Why Electric Boilers Aren’t the Answer

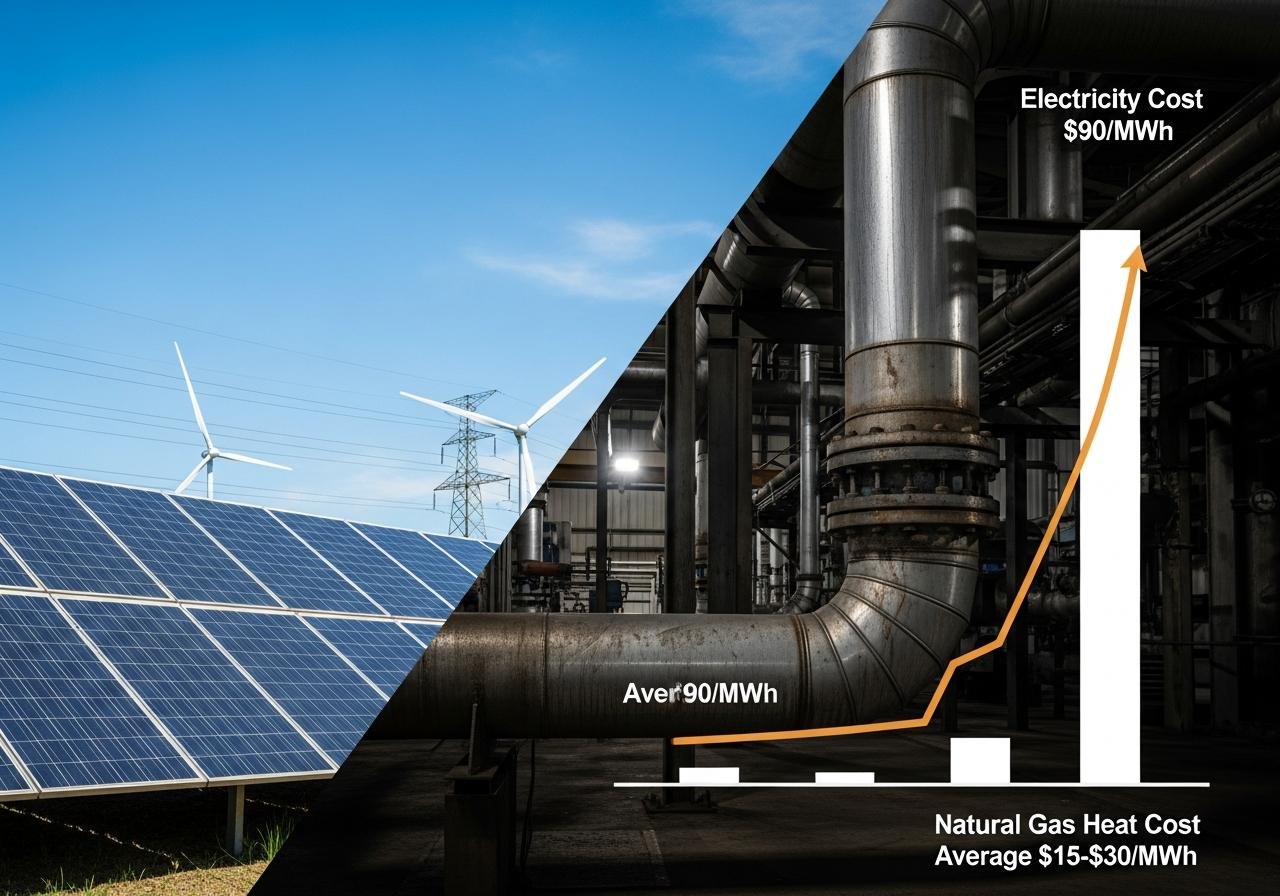

At first glance, replacing gas boilers with electric ones seems like an obvious fix. Electric resistance boilers convert electricity directly into heat, boasting efficiencies of 98–99%, far higher than typical gas boilers at around 80%. But here’s the catch: electricity costs.

While renewable electricity is getting cheaper, industrial electricity prices in the U.S. still average about $90 per megawatt-hour. In contrast, the heat from burning natural gas costs just $15 to $30 per megawatt-hour. That means switching to electric resistive boilers could make steam production three to six times more expensive — a non-starter for most factories.

The Magic of Heat Pumps for Industry

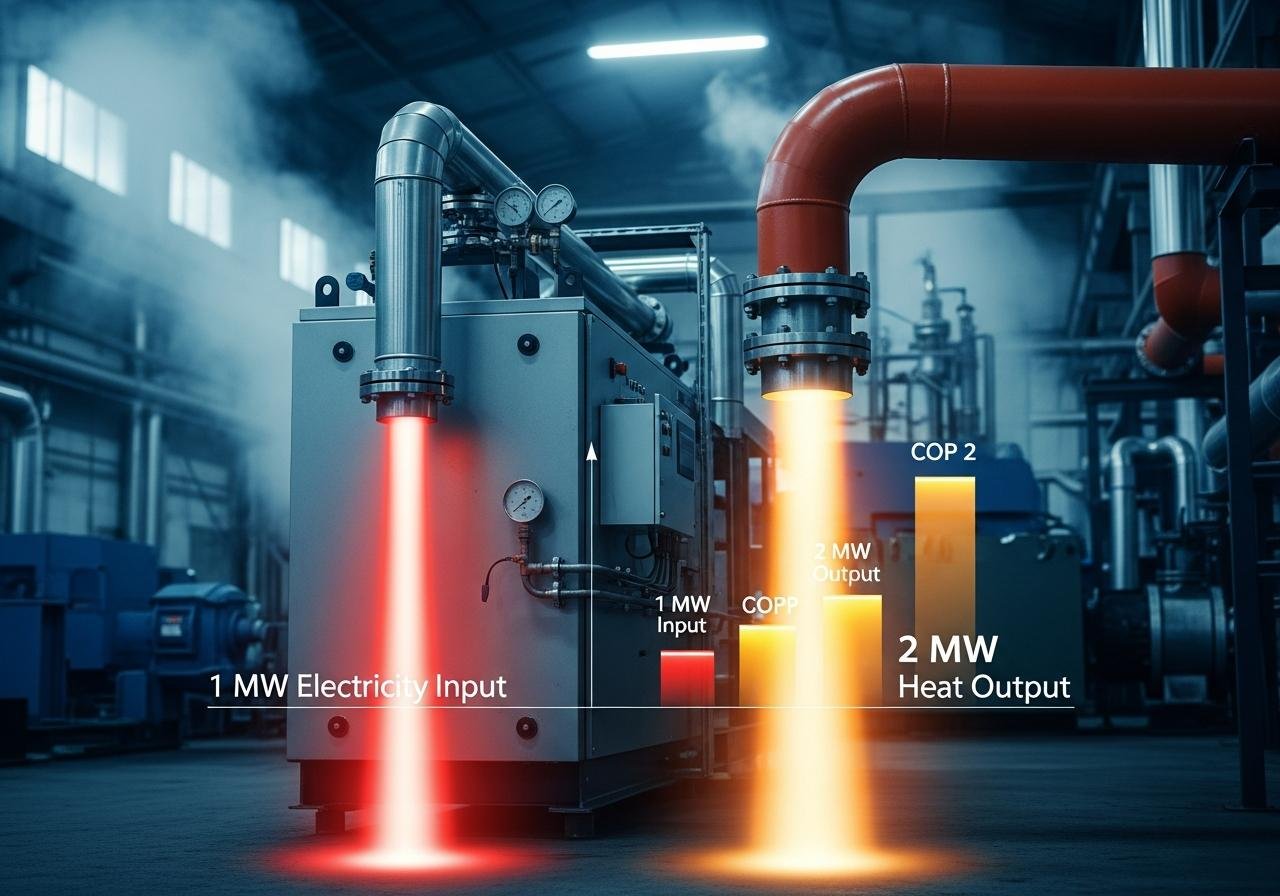

Rather than creating heat, heat pumps move it — just like an air conditioner transferring heat from inside your home to the outside. This gives them a unique efficiency edge. Their performance is measured by the coefficient of performance (COP). A COP of 1 equals a resistive heater, while a COP of 2, 3, or 4 means you’re delivering two, three, or four times more heat energy than the electricity consumed.

Atmos Zero’s Boiler 2.0 system operates at a COP of roughly 2. In simple terms, for every 1 megawatt of electricity it consumes, it delivers 2 megawatts of heat. That effectively halves the cost of producing steam compared to resistive heating — making clean steam both sustainable and financially viable.

How Atmos Zero’s Two-Stage Heat Pump Works

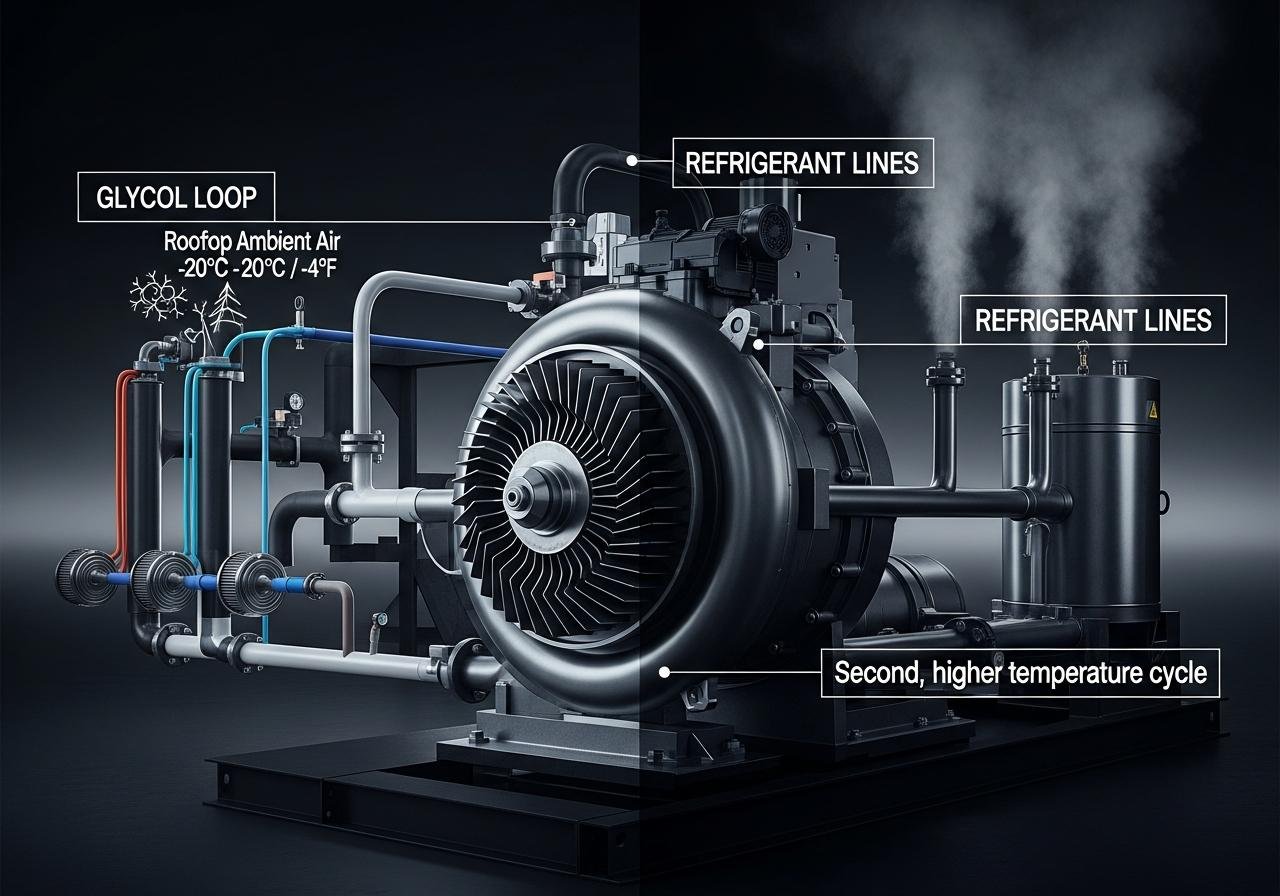

The real innovation lies in how Atmos Zero achieves such high temperatures — up to 250°C (482°F) — starting from frigid air as cold as -20°C (-4°F). The system uses a two-stage heat pump cycle:

Stage One: A glycol loop absorbs heat from ambient air through rooftop heat exchangers, even when it’s freezing outside. This pre-heated fluid then transfers its energy to the first heat pump cycle, where a refrigerant evaporates and is compressed by a high-speed centrifugal compressor derived from automotive turbocharger technology spinning at 30,000 RPM (discover more on how emerging technologies play a role in this sector here).

Stage Two: Instead of sending this heat directly to steam, it feeds into a second, higher-temperature cycle. This double-compression process boosts the temperature high enough to flash-boil feedwater into high-pressure steam — all without combustion.

Scaling with Simplicity: Why Standardization Wins

Some engineers might ask: why not use waste heat from the factory itself? After all, recovering heat from industrial processes could further increase efficiency and lower operating costs. But Atmos Zero made a deliberate choice to stick with ambient air rather than custom waste-heat systems — and it comes down to scalability.

Balancing Engineering and Economics

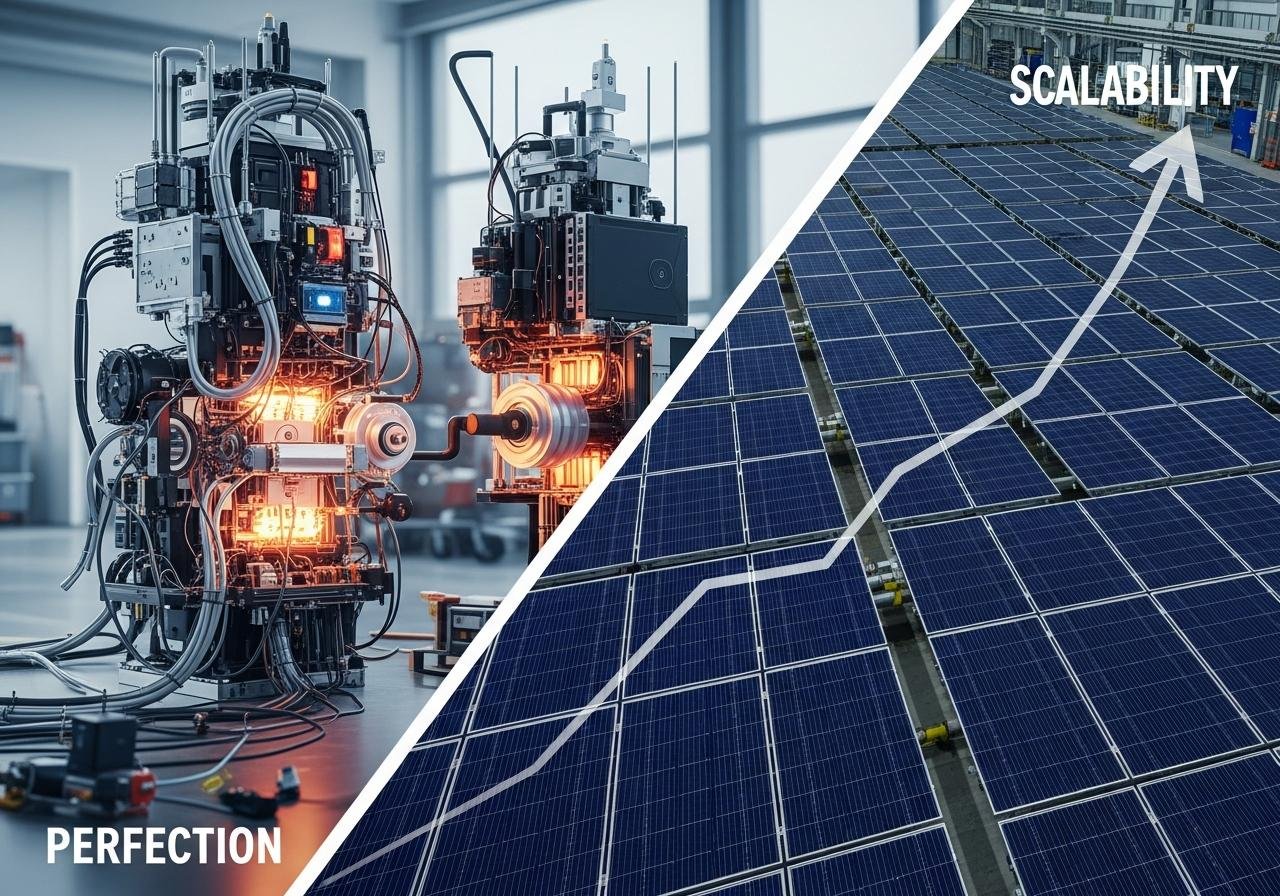

Atmos Zero’s approach reflects a critical shift in climate technology design — prioritizing scalability over perfection. The clean energy sector is full of brilliant solutions that never left the prototype stage because they were too costly or complicated to deploy. By focusing on affordability and simplicity, Atmos Zero ensures that its product can actually reach market scale, where it can make a measurable dent in emissions.

It’s a lesson learned from companies like Exawatt, which developed modular solar systems by trading off some performance for manufacturability. The same principle applies here: a solution that’s 90% as efficient but 10 times easier to adopt can transform an industry faster than one that’s technically flawless but economically prohibitive.

Redefining Industrial Decarbonization

Industrial heat has long been stuck in what experts call a “valley of death” between two extremes. On one side, simple but expensive electric boilers are easy to adopt but unaffordable to operate. On the other, ultra-efficient custom heat pump systems deliver low running costs but require massive upfront investment and long payback periods. Atmos Zero bridges that gap.

By delivering a standardized, affordable, and scalable clean steam solution, this young company offers a path for manufacturers to decarbonize without overhauling their entire operations. It’s not the flashy, hyper-optimized approach — it’s the practical one. And that’s precisely what the climate fight needs right now: fast, achievable transitions that work in the real world.

The Future of Clean Steam

As the world races to decarbonize, clean industrial heat remains one of the toughest frontiers. Atmos Zero’s technology arrives at a pivotal time, bridging innovation and practicality. With plans for mass production beginning in 2026, the company could soon supply hundreds of industrial boilers annually — each one displacing fossil fuels, cutting emissions, and proving that even the oldest industrial processes can adapt to a zero-carbon future (learn about other technologies contributing to this transition

Reference:

The post Atmos Zero – Industrial Steam Heat Pump appeared first on Green.org.