Precision Planting engineers believe they have solved the challenge of orienting seeds properly, with the launch of ArrowTube.

People planting seeds by hand know that the pokey end goes down, but getting that to happen in modern planters on a large percentage of seeds at 10 miles per hour has been a challenge.

WHY IT MATTERS: Plant emergence advantages from precision planters help to create more resilient and higher-yielding crops.

Precision Planting announced its ArrowTube seed tube at its annual Winter Conference in January. This was the first year the event was branded PTx to reflect the merging of the Trimble and Precision Planting businesses owned by Agco into one business brand.

The conference happens in-person at one location in the United States, then is broadcast to other locations across North America, including in Waterloo.

Even stand

The goal of many of the innovations in planter technology in the past decade — including singulation, down pressure and precise metering — is to get more uniform emergence.

A crop with plants that emerge at the same time and grow at the same rate helps maximize each plants’ yield and ability the harvest sunlight.

“Thirty-six to 48 hours delayed emergence of individual plants will yield 30 to 60 per cent below the plants that came out of the ground on time,” said Cory Muhlbauer, a research agronomist with Precision Planting.

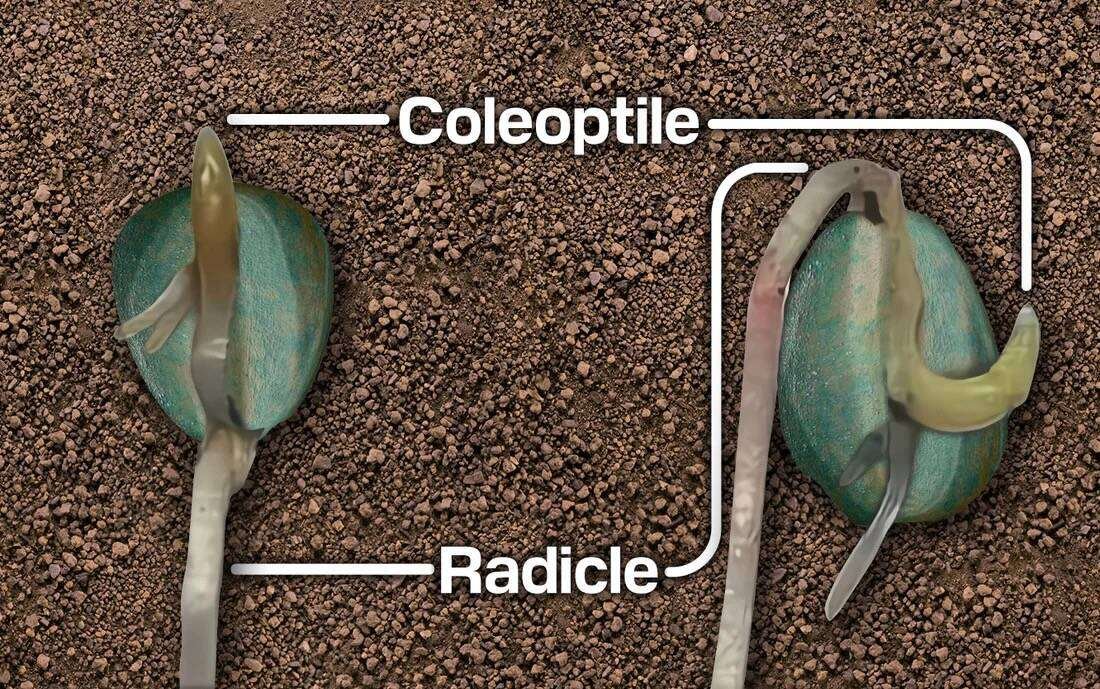

The idea behind seed orientation is simple. When a seed is planted with the tip down, the radicle root grows away from the tip and down into the ground, and the coleoptile grows out from the embryo and straight up to the surface of the ground. A seed that is on its side, especially embryo-side down, means the coleoptile must grow around the seed and then up to the surface.

Seeds know, due to their response to gravity, which way the root should grow.

This enables the plants to find their way to the surface, even if the seed is misoriented.

Seed orientation also affects the way the leaves grow early on and that can affect how much sunlight the plant will be able to absorb, said Muhlbauer.

“It’s an interesting opportunity when we talk about these little plants being solar factories, and we want to maximize their efficiency and output.”

Many iterations

Researchers established more than a decade ago that seeds planted manually with the tip down will yield more. Research in 2012 and 2013 by Pioneer, Oklahoma State University and Illinois State University showed a yield increase that ranged from nine to 29 per cent. Those studies were small plots in perfection conditions, said Jeremy Hodel, a Precision Planting product manager.

But engineers hadn’t been able to make seed orientation practical at high speeds, until now.

Precision Planting took four years to figure it out.

The company created a new seed tube that has a helix shape that holds the seed tip down with centrifugal force to the soil, but it’s the accelerator unit on top of the tube that orients the seed.

Seeds have a centre of gravity, said Ryan Baker, an engineer with Precision Planting.

The company figured out how to use friction and a guide wall to move the seed to the moment at which it flips to tip forward.

Baker said seeds come off the seed meter and counter rotating wheels put the seed around a loop, during which friction and the guide wall flip the seeds to tip forward. The helix shape of the tube also helps to flip more of the seeds.

Once the seed is oriented and ready to drop into the furrow, Precision Planting designed a new knife that sits 5/8ths of an inch lower than a convention furrow bottom. The narrower slot at the bottom of the furrow allows for the seed to sit in the slot, without the rolling that happens in other systems.

The company says that the system also works to orient soybeans, although at less accuracy than corn.

What about yield?

Precision Planting used a split planter to do side-by-side trials of the ArrowTube and convention seed tubes and covered about 3,000 acres.

Hodel said in a follow-up question that he’s leery of doing yield comparisons on technology that’s still being developed, but that versus an ExactEmerge control the ArrowTube had a 6.4 bushel per acre advantage and a rep win rate of 87 per cent over 52 repetitions at seven locations.

Precision Planting catalogued about 7,000 plants for their seed orientation and emergence. Hodel says that a conventional planter got the seed tip down about 12 per cent of the time, while ArrowTube was about 62 per cent of the time. If the two most-beneficial orientations are counted — tip down and embryo up — ArrowTube oriented the seeds almost 90 per cent of the time.

“At the end of the day, from an emergence standpoint, then we saw a reduction in the number of late emerges by 18 per cent,” said Hodel.

The post ArrowTube orients seeds tip-down in planters appeared first on Farmtario.