Aluminum is moving from a supporting role to center stage in the global green transition. The metal is light and strong, and also endlessly recyclable. This makes it essential for electric vehicles (EVs), solar panels, power lines, and low-carbon buildings.

Global demand for aluminum is rising fast as countries expand renewable power and electric transport. The International Aluminium Institute (IAI) expects aluminum demand to rise by 40% by 2030. This growth is fueled by clean-tech uses.

But as the market expands, so does scrutiny on emissions. Aluminum smelting is one of the most energy-intensive industrial processes in the world. Reducing its carbon footprint is now a top goal for both industry and governments.

Aluminum Prices Hit 3-Year High Amid Tight Supply

On October 10, 2025, aluminum prices surged to their highest level in three years, topping around $2,800 per tonne. The rally shows rising supply worries and increasing demand from clean energy sectors. This includes electric vehicles (EVs), renewable power, and construction.

Analysts attribute the spike to several factors. China’s power shortages have limited smelting output. Also, new environmental rules are tightening production limits on coal-powered plants. In addition, unrest in Guinea, which supplies over 45% of China’s bauxite imports, has raised fears of disruptions in the global supply chain.

Meanwhile, inventories tracked by the London Metal Exchange fell to their lowest point since 2021, signaling a tightening market.

“Supply can’t keep up with the clean-energy boom,” said analysts from BloombergNEF. They pointed out that aluminum’s use in solar, EVs, and transmission lines is growing faster than producers can adapt.

The recent price rise shows that investors prefer low-carbon aluminum. This type of aluminum now has a significant premium. Demand for verified low-emission materials is outpacing supply. This is the case for automakers, construction firms, and renewable developers in Europe and North America.

Experts think that prices over $2,500 per tonne could boost investments in recycling and renewable-powered smelters. This is especially true in places like Canada, Norway, and the Middle East. However, the rally also underscores a broader challenge: balancing the green transition with resource security.

Why Aluminum Is the Unsung Hero of Clean Energy

Aluminum saves weight — and that means energy. Lighter cars and trucks travel farther on the same battery charge. According to the Aluminum Association, modern EVs use 30–40% more aluminum than traditional gas vehicles.

It’s not just cars. Each 1-MW solar farm uses roughly 40 tons of aluminum for panel frames, mounts, and wiring. Power grids also rely on aluminum for transformers and long-distance transmission lines.

The metal’s high recyclability adds major sustainability value. Recycled aluminum uses only 5% of the energy required for primary production. Yet recycling accounts for only about 36% of global aluminum output today, leaving huge room for expansion.

The low-carbon aluminum market was 19.3 million tons in 2024, per IMARC estimates. It can grow to 27.7 million tons by 2033, with an annual growth rate of 3.7%. That growth mirrors global renewable investment trends.

China’s Dominance and the Global Supply Imbalance

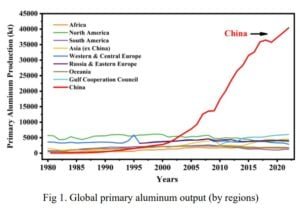

China dominates the aluminum industry. It produces over 40 million tons of primary aluminum annually — nearly 60% of global supply. It also tops in refining and processing, as well as in demand for raw materials like bauxite.

Exports of bauxite from Guinea to China jumped 35% in 2024, making Guinea the world’s top bauxite exporter. This raw material feeds China’s vast smelting network.

Worldwide, primary aluminum production has topped 70 million tons in recent years. But the carbon footprint varies greatly by location.

Smelters powered by coal — common in parts of China — emit far more CO₂ than those powered by renewables. Producers in Norway, Iceland, and Canada use hydropower. They create aluminum with emissions below 4 kg CO₂ per kg aluminum. This is much lower than the global average of 16.7 kg CO₂ per kg (IAI, Hydro).

This huge gap shows why energy source matters as much as output in the global supply chain.

The Emissions Problem — and Low-Carbon Solutions

Traditional aluminum production is energy-hungry. The International Energy Agency (IEA) estimates that aluminum accounts for around 2% of global CO₂ emissions from materials production.

Producers are now turning to renewable power and recycled inputs to cut this footprint. Norsk Hydro, for example, produces low-carbon aluminum emitting only 3 kg CO₂/kg, among the world’s cleanest.

If all smelters switched to renewable power, global aluminum emissions could fall by 400 million tonnes of CO₂ each year. That’s like the yearly emissions from 100 coal plants.

Recycling is another big win. Recycling rates in Europe could double by 2030, potentially saving 39 million tonnes of CO₂ per year by 2050. Globally, if all used aluminum were recycled, the industry’s total energy demand could fall by 60%, says MARC Group.

Pricing, Premiums, and the Push for Low-Carbon Metal

Aluminum remains a major commodity. The global aluminum market was valued at roughly $190 billion in 2024, with steady growth projected through 2030.

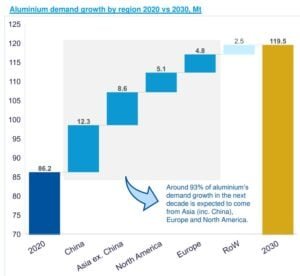

The IAI forecasted the following for aluminum demand growth by 2030:

-

By Region:

Around 93% of global aluminum demand growth between 2020 and 2030 will come from Asia (especially China), Europe, and North America, reflecting industrial expansion, renewable power deployment, and strong EV manufacturing in these regions.

-

By Sector:

Aluminum demand is set to grow most in transportation (+11.8 Mt), followed by electrical (+5.2 Mt), construction (+4.6 Mt), and packaging (+3.3 Mt) — with transport leading due to electric mobility and the electrical sector driven largely by solar and renewable infrastructure. -

By EV Demand:

Electric vehicles will account for roughly 63% of new aluminum demand in transport, adding about 7.4 million tonnes by 2030; EVs use 60–80 kg more aluminum per vehicle than traditional models, with China, Europe, and North America driving about 93% of this growth.

Low-carbon aluminum commands a premium. Market data shows that buyers pay $20 to $150 per tonne more for certified low-carbon products, depending on the region and energy source.

Smelters that use renewable power gain a cost edge as carbon pricing expands. For instance, hydropower-based smelters in Iceland and Quebec report operating costs up to 30% lower than coal-based plants in China.

Investment in renewable-powered smelting hubs is also accelerating. In 2025, new projects in Europe, Canada, and the Middle East are expected to increase global capacity for low-carbon aluminum by 3–4 million tons.

Industry Moves, Policy Levers, and Challenges Ahead

Automakers, electronics makers, and construction firms are driving the shift. Mercedes-Benz, Apple, and Volvo all signed long-term contracts for low-carbon aluminum to cut supply chain emissions.

The European Union’s Carbon Border Adjustment Mechanism (CBAM), set to take effect in 2026, will tax imports based on embedded CO₂. This policy will pressure high-emission producers to decarbonize faster.

Governments are also funding clean smelting projects. In 2025, the U.S. Department of Energy awarded over $500 million program. This program aims to boost aluminum decarbonization and improve recycling infrastructure.

Countries rich in bauxite, like Guinea and Indonesia, are enjoying higher global demand. However, they also face pressure to improve environmental standards in mining and refining.

Scaling low-carbon aluminum faces three main challenges:

- Energy transition: Replacing fossil electricity with renewables near smelters requires billions in new investments.

- Recycling infrastructure: Global collection systems remain fragmented; less than 40% of post-consumer scrap is recovered.

- Verification: Without strict standards, false “green aluminum” claims risk damaging trust.

Aluminum could become one of the biggest enablers of decarbonization. Every tonne of low-carbon aluminum can reduce lifecycle emissions in cars, solar farms, and power lines by several tonnes of CO₂.

To meet climate goals, producers, investors, and governments must collaborate. Expanding renewable energy for smelting is key. Scaling up recycling is also important, as well as having traceable and verified supply chains to succeed.

With the right policies and innovation, aluminum can become a cleaner material. It can support the energy transition by helping create lighter, stronger, and more sustainable systems.

The post Aluminum Prices Hit 3-Year High: Is It the Next Key Metal in the Clean Energy Shift? appeared first on Carbon Credits.