[Disclosure: AgFunderNews’ parent company AgFunder is an investor in Bluemethane.]

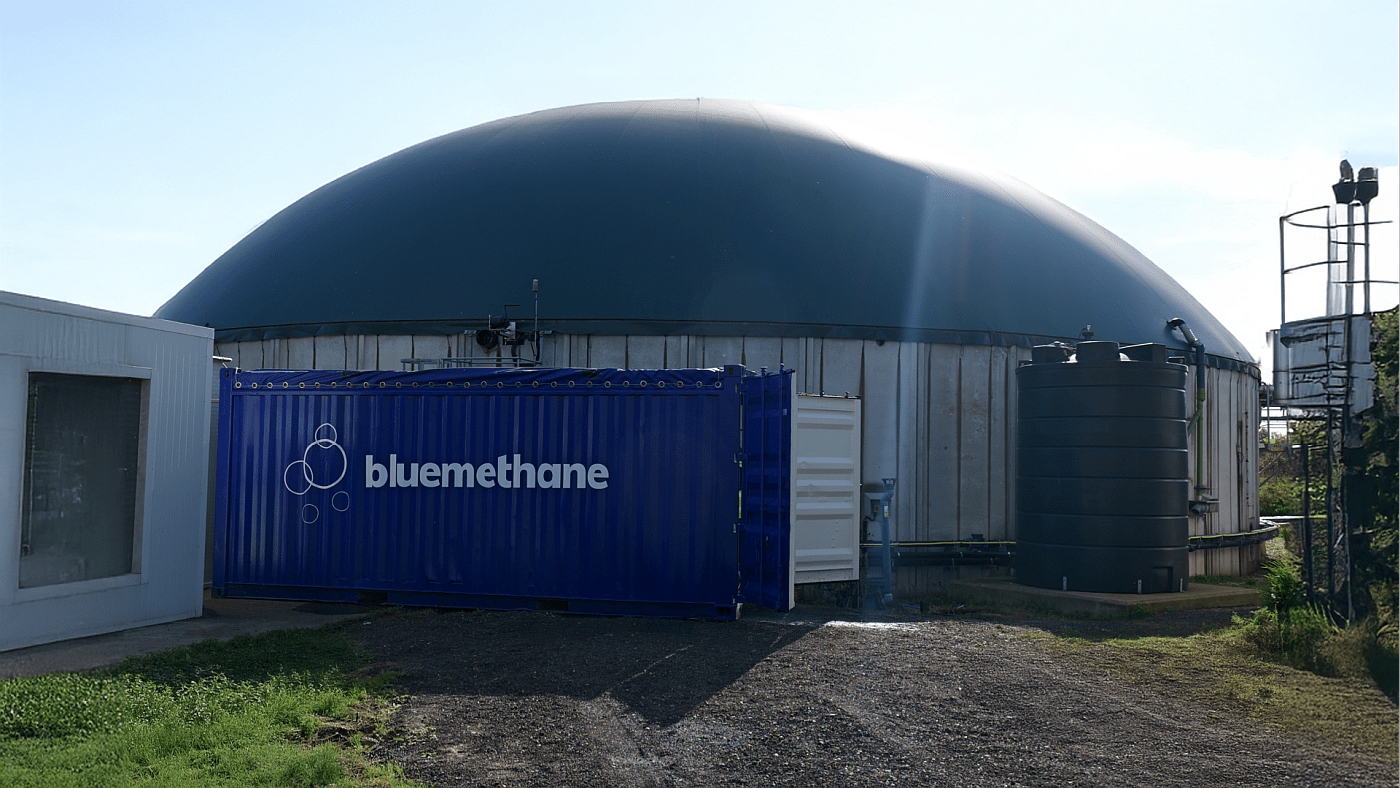

Bluemethane—a UK startup on a mission to unlock the value of methane in water and waste streams—has deployed its first production-scale methane-capture unit with partner ReGenEarth at a biogas plant on the Isle of Wight off the south coast of England.

Anaerobic digesters deploy microbes to convert organic matter into biogas (methane and carbon dioxide). However, some methane remains in the post-digested sludge or “digestate,” representing both lost value and a source of emissions.

The first methane-abatement system of its kind to be installed at a biomass site, Bluemethane’s unit captures the residual methane in the digestate using physical separation technology that can fit inside a 20-foot container, said CEO Louise Parlons Bentata, who cofounded Bluemethane in 2021 with engineer Nestor Rueda-Vallejo.

“Think about holding a bottle of sparkling water where you don’t really see the bubbles inside, but when you shake it and open the lid, it fizzes. By shaking it, you speed up that process of the bubbles coming out and by opening it, you suddenly change the pressure. We replicate that process using turbulence to speed up the process of separation driven by gravity.

“Entering our system is the liquid containing dissolved methane, and we end up with a stream of biogas that contains methane and carbon dioxide. We can also recirculate the same sludge multiple times if the microbes continue to make more methane.”

The ROI at the biogas site—with Bluemethane’s unit installed downstream of the digester—is threefold, she says. First, the captured methane can increase the site’s biogas production, generating more revenue. Second, it can improve operational efficiency, because sites can use less feedstock to get the same amount of energy. And third, it can generate carbon avoidance credits, which reward projects that prevent emissions that would otherwise occur.

While avoidance credits can get a bad rap, said Parlons Bentata, they are not all created equal. “It definitely depends on the quality of the credit. But we are measuring it and removing it and it’s burned within a couple of days, so there’s full traceability. That said, we are not building a business case around the carbon market.”

She added: “I remain skeptical about the carbon market and our business model doesn’t depend on them. If you are only about carbon markets, you’re in trouble.”

Anglian Water pilot testing

A second Bluemethane unit is being piloted by Anglian Water, which provides water and wastewater services, to recover residual methane from anaerobic digester effluent.

In this case, the unit will help Anglian Water comply with environmental regulations (the UK version of the EU Industrial Emissions Directive) that set strict rules on pollution from large industrial installations including wastewater treatment plants, says Parlons Bentata.

“They have to reduce total emissions to down to a very low level, which means covering open tanks [containing digestate].”

Three revenue streams

Stepping back, Bluemethane can potentially generate revenue in three ways, says Parlons Bentata: Installations at anaerobic digestion sites at biogas plants or water treatment sites; paid methane measurement projects; and deactivating methane-producing microbes to trigger additional value by preventing downstream scope three emissions.

The first is just beginning to gain traction, but work is also progressing nicely on the second and third, she said.

“We’re working with Scottish Water, United Utilities, and Cranfield University to develop a first of its kind measuring system to determine how much methane is in a liquid waste stream, and that’s supported by a DEFRA [Dept for Environment, Food & Rural Affairs] grant.”

This will provide precise data on the amount of methane present in various liquid waste streams, she said. “The initial results are very promising. This improved measurement capability will be crucial for optimizing the performance of our technology and providing our customers with the data they need for effective methane management and reporting.”

For methanogen deactivation, meanwhile, Bluemethane is working on a project with four UK water companies “so we can help them trigger additional value by preventing downstream scope three emissions,” she added.

‘We’re not easy to categorize, you can’t put us in a nice box’

Bluemethane can represent a challenge for investors because methane capture from liquids is very new, and potential backers don’t always know how to assess the company, she says.

“We’re not easy to categorize, you can’t put us in a nice box… but this market really is ours for the taking. For water companies, we’re also the most cost-effective way to achieve compliance with environmental regulations.

“For dairy farmers [with anaerobic digestors on site] it’s more of an insetting model. The question then is how much will the big brands pay to reduce emissions on their milk and how much will they pay Bluemethane for decarbonizing their supply chain?”

The post Bluemethane deploys first production-scale methane-capture unit at biogas plant appeared first on AgFunderNews.