Surfactants make modern life clean, efficient, and comfortable. They are in everything from shampoo to soap, lotions to laundry detergents. However, surfactant producers are keenly aware that they need to reduce their carbon footprint and create more sustainable supply chains in order to future-proof their businesses.

Many traditional surfactants rely on fossil-based resources, which are not only finite, but costly as well. Many companies are looking for cleaner, smarter alternatives, and some are moving to bio-based solutions. However, a new innovation from Econic Technologies adds a new tool to the sustainable surfactants toolbox: Captured carbon.

The global surfactant market in 2025

In 2025, the global surfactant market reached nearly 19 million tons¹, highlighting the continued success and widespread adoption of surfactants across industries worldwide. This milestone reflects both the versatility of surfactants and their critical role in everything from household cleaning to personal care and industrial applications.

Behind this acceleration lies our dependence on fossil fuels (oil, natural gas, and coal) to power our energy systems and act as building blocks in the chemicals and materials that are embedded within our everyday lives. The chemical industry accounts for 6% of global greenhouse gas emissions².

Furthermore, the demand for primary chemicals, which tend to be energy-intensive, is projected to increase by 2.3 times by 2050³. Despite their significant environmental footprint, chemicals remain indispensable, enabling vital products from hospital plastics to advanced coatings that improve the longevity of everyday items.

A significant proportion of traditional surfactants are comprised of fossil-based epoxides (ethylene oxide) and fatty alcohols derived from fossil- and bio-based feedstocks. The opportunity lies not with how we can replace these versatile chemicals, but instead how we can utilize alternative sources of carbon to replace traditional feedstocks. To succeed in meeting net zero by 2050, transitioning towards renewable carbon feedstocks (biomass, captured CO₂, and recycled carbon) is non-negotiable.

Unlocking captured carbon for surfactants

Alternative technologies are already starting to reshape the industry. Through carbon capture and utilization (CCU), scientists now have the opportunity to turn carbon dioxide (that would be treated as waste) into valuable new surfactants—paving the way for cleaner, more sustainable chemical solutions.

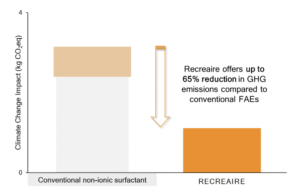

Advancing this technological change is Recreaire®, a CO₂-based surfactant platform that uses captured carbon dioxide as a raw material. This replaces traditional oleochemicals and a portion of fossil feedstocks with a renewable source of carbon. With Recreaire, surfactant producers can reduce climate change impact by up to 65% compared with conventional surfactants.

Life Cycle Assessment (LCA) provides quantitative analysis of the environmental impacts across the surfactant value chain. Studies show conventional surfactants can result in global warming potentials (GWP) of 2.2–3.6 kg CO₂e/kg product, mainly due to fossil-derived feedstocks and energy inputs. CCU-enabled pathways—using CO₂ captured from industrial flue gases, direct air capture, or biogenic sources—dramatically reduce GWP. LCAs extend to the consequences on waste, energy use in manufacturing, and product end-of-life, guiding industry toward continuous sustainable improvement.

This LCA is based on preliminary life-cycle data and has not been subjected to independent third-party review. Assessment is conducted on a cradle-to-gate system.

Carbon capture utilization and the circular economy

Renewable surfactants can flip the script on the chemical industry. CCU reimagines CO₂ as a raw material, integrating chemical production with circular economy principles. Each molecule of carbon captured and reused in this way helps close the loop by taking it out of the atmosphere and reducing society’s dependence on underground carbon and oleochemicals, such as food-grade natural oils.

That’s not only good for the environment; it has a great business case, too. “One of the biggest advantages of Recreaire is how easily it fits into existing production setups,” said Simon Bennett, Commercial Director for Surfactants at Econic. “Producers don’t need to overhaul their plants or reinvent their processes—Recreaire technology can be incorporated with minimal change, making the shift to lower-carbon surfactants far simpler than many expect.”

Carbon dioxide is abundant, and available at a much lower cost than the fossil materials it replaces. With CCU, almost every supply chain has the potential to be a local supply chain, improving supply chain resilience.

With the surfactants market expected to grow by 4% annually until 2030, breakthrough technologies like Recreaire are essential to curb the carbon footprint of everyday products while meeting societal needs. True progress will come when the chemistry that cleans our homes also helps clean up the atmosphere.

In conclusion

Recreaire is a powerful new technology platform that shows how cutting-edge carbon capture and utilisation can unlock performance, scalability, and real environmental progress for the surfactants industry. It adds one more tool to the toolbox of sustainability leaders who want to reduce the carbon footprint of their products, and do so while creating effective products in an economical way.

References

¹ Surfactants Market – Size, Manufacturers, Industry Share & Growth

² Defossilising the chemical industry | Royal Society

³ WEF_Net_Zero_Industry_Tracker_2024_Primary_Chemicals.pdf

This article was written by Joe Evans, Econic’s Environmental Specialist. To learn more or contact Joe, click here.

The post Climate Change Challenge: Defossilizing Surfactants appeared first on Econic Technologies.