Israeli agtech startup DailyRobotics is gearing up for commercial launch in California next April with a robotic harvester it claims can pick strawberries 2-3x faster than humans.

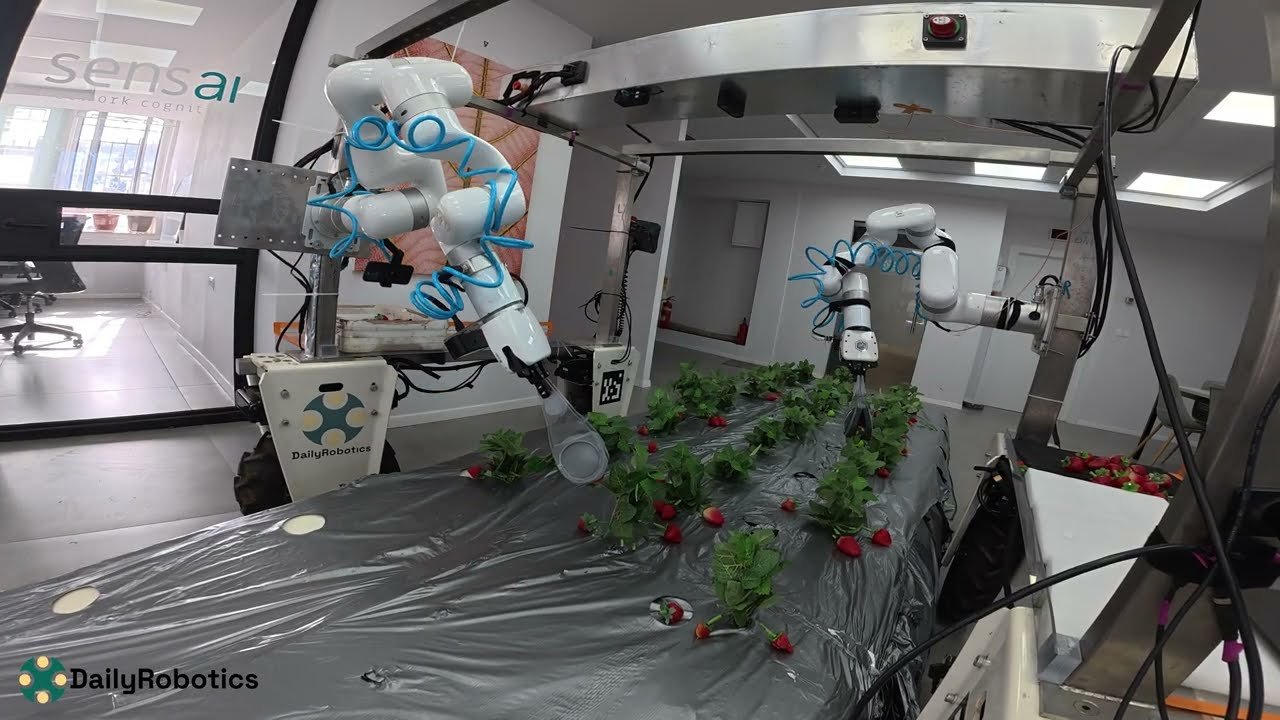

The Q2 harvester, which is designed for field-grown strawberries, has two robotic arms and soft grippers that gently pick the fruit and place it directly into clamshells, cofounder Adham Ghazali tells AgFunderNews.

“Our current field performance is around 30 kg/hour, and the hardware is already capable of reaching 50 kg/hour as we continue optimizing software and cycle time. One operator can manage up to eight robots, and Q2 packs strawberries directly into clamshells, fitting smoothly into existing farm workflows.”

Designed for plant beds at widths of 2.2-4.6 feet, the battery-powered ‘bot performs both harvesting and on-board quality grading, says Ghazali. “Each berry is imaged and evaluated by a perception pipeline that classifies size, surface defects, color maturity, and over-ripeness, and the manipulator then places it into the corresponding bin or clamshell. This closed-loop process ensures uniform pack quality directly in the field.”

As strawberries are often hidden underneath leaves, meanwhile, “We have a dynamic perception system that’s able to search for strawberries because the arm goes into the canopy with a camera,” he says.

Why it matters

Strawberries are a high-value but labor-intensive crop that is typically picked by hand in most parts of the world, says Ghazali, who previously led vision-based self-driving car startup Imagry. Growers struggling with labor costs and availability are looking for better options that will save time and money.

“Our focus is robotics as a service (RaaS) but we’re also open to selling the machines, so we can refine the business model. But our primary objective is to solve a problem and prove that we can reduce labor costs.

“In California, it can cost $43,000 per acre per year for picking alone, and there are thousands of acres of strawberry farms in California. And in some places up to 30% of the crop can be left to rot on the floor.”

As California strawberries are harvested for much of the year with regional hand-offs (each region has its own peak season), the ‘bots can be moved around as needed to meet regional demand, he adds.

Rise of the machines

Founded in 2023 by Adham Ghazali, Majed Jubeh, and Farah Jubran, who have expertise in robotics, AI, and large-scale engineering, DailyRobotics has not yet taken on VC money, says Ghazali. Funding to date has come from the founders, a non-dilutive grant, and angel investors.

DailyRobotics is not the only game in town when it comes to robotic strawberry harvesting, and is just one of several startups in the space including L5, Harvest CROO Robotics, Agrobot, Organifarms, Fieldwork Robotics, Dogtooth Tech and Tortuga AgTech, which is now part of Oishii.

Most are still in the trial phase, with some focusing on tabletop/greenhouse-grown fruit (Oishii, Organifarms), while others such as DailyRobotics and Harvest CROO Robotics focus on open field-grown fruit.

For picking, meanwhile, they all use slightly different approaches. Some gently grab the berries with a soft claw cutting and others grip the stems, cutting them and dropping the fruit into boxes, an approach that Ghazali says works well in greenhouses but is more challenging in open fields.

According to Ghazali, the key factors for robotic strawberry harvesting are:

👉 Speed vs cost: Humans are extremely efficient at fruit picking, says Ghazali. And if robot pickers go too slow, he says, “there’s really no business model.” But as you increase the speed, the potential for damage becomes much, much higher, he says. “We can pick 2-3x as fast as humans and it’s much more scalable with more robotic arms.”

👉 Integration with existing operations: “It’s not just about picking,” he says, it’s about real-time quality control. Effective ‘bots must be able to sort fruit as well as pick and pack it. “Once we see a strawberry, we can automatically classify it.”

👉 Bruising/damage rate: DailyRobotics is developing a new soft gripper that gently “hugs” the fruit without squeezing it, says Ghazali. “In recent field tests, the end-to-end picking process achieved a ~4% bruising rate, which falls within the expected range for skilled hand-picking under similar conditions.”

👉 Charging: According to Ghazali, the ‘bots are designed to work for a full day before needing recharging (using a regular socket and power supply), although users can also replace batteries in the field.

👉 Manufacturing/scale up: “We have a very simple design using OEM ready equipment and tools,” he says. “Our robots can be assembled in under an hour. The hardware we use is already mature and mass-produced, which makes manufacturing cost very low. The only thing that is manufactured in-house is the grippers.”

👉 Maintenance: “You have to have something that doesn’t require a lot of support,” says Ghazali. “Operators can scan a QR code on the unit to access a mobile maintenance interface that provides real-time diagnostics, subsystem health monitoring, error logs, remote control functions, and live support tools, all without requiring specialized equipment.”

What’s next?

More field trials: “We’re going to do more field trials from now until April.”

Commercialization: “We are deploying our first robots with a customer in California starting in April 2026.”

Further reading:

🎥‘Like a Roomba for vineyards…’ Bien Nacido puts Saga Robotics’ UV-C robots to the test

Ag robotics startup Naïo bounces back after a year of financial turmoil

Carbon Robotics founder Paul Mikesell on agtech: ‘Be careful how you talk about it’

Farm robotics in the weeds as funding declines 36% from Q2 to Q3

The post DailyRobotics enters strawberry harvesting race with robot that can pick 2–3x faster than humans appeared first on AgFunderNews.