The chemical industry is under increasing pressure to decarbonize, diversify feedstocks, and future-proof operations. At the Netherlands Organization for Applied Scientific Research (TNO), a leading independent R&D organization, scientists are working to accelerate the industrial adoption of innovative technologies. One such area is electrosynthesis, where TNO is demonstrating how biobased furfural can serve as a versatile platform chemical for producing a range of high-value products.

This is not the only route under development, but it serves as a compelling demonstration of how electrochemistry can unlock new value chains from renewable feedstocks.

Why Furfural?

Furfural is derived from agricultural residues and offers a renewable alternative to fossil-based building blocks. It has already proven its industrial relevance in the PERFORM project, where TNO successfully scaled the conversion of furfural into maleic acid, a key intermediate in polyester resins with applications in composite materials, paints, coatings, adhesives and lubricants.. This pilot-scale success (multiple kg/day throughput) shows that furfural-based processes can meet industrial performance benchmarks.

Beyond maleic acid, furfural can be electrochemically converted into furoic acid, used in fragrances and food additives, and hydrofuroin, a precursor to sustainable aviation fuel. These products span both established markets and emerging sectors, offering flexibility for portfolio diversification.

In 2026, TNO will further develop these pathways, with at least one targeted for scale-up to pilot level, reinforcing the commercial viability of furfural-based electrosynthesis.

The Strategic Advantage of Electrochemistry

Electrochemistry provides a unique set of control parameters—such as electrical potential, temperature, and catalyst selection—that allow for precise tuning of chemical reactions. This level of control enables selective synthesis, reducing by-products and improving process efficiency.

From an operational standpoint, electrosynthesis is inherently more energy-efficient than thermochemical processes. It uses electricity directly to drive reactions, eliminating the need for high temperatures and pressures. When powered by renewable energy, the sustainability profile of the process is significantly enhanced—making it attractive for companies looking to meet ESG targets and regulatory requirements.

Bridging Innovation and Industrial Scale

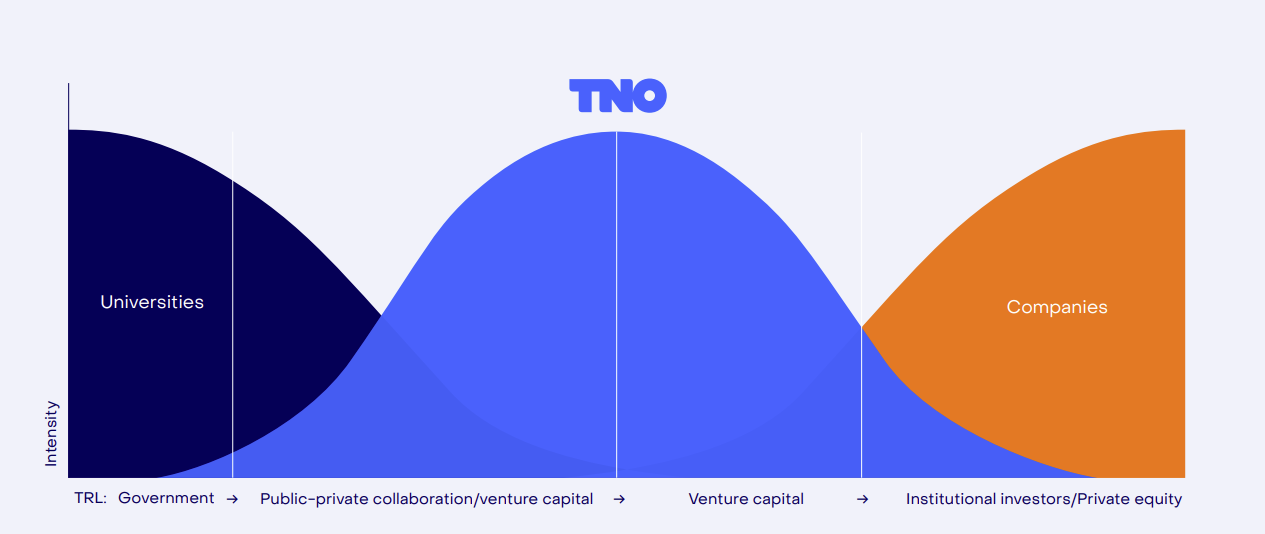

Despite its promise, electrochemistry has yet to be widely adopted in the chemical industry. Academic research has made significant strides, but translating lab-scale breakthroughs into industrial processes remains a challenge. TNO addresses this gap—often referred to as the “Valley of Death”—by providing the infrastructure and expertise needed to scale up innovations.

TNO’s modular pilot systems allow for rapid iteration and optimization. Starting from flow cells with 5–100 cm² catalyst surface areas, processes are scaled up to skids with 1000 cm² and even 1 m² electrodes. These systems can produce few tons of product per year under continuous operation, with integrated monitoring and downstream processing to ensure product quality and purity.

This approach de-risks scale-up for industry partners and shortens time-to-market for new technologies.

Commercialization Opportunities

For stakeholders in specialty chemicals, polymers, fuels, and fragrances, the furfural-electrosynthesis platform offers:

- Feedstock flexibility: Use of renewable, non-food biomass.

- Product diversity: Access to both commodity and niche chemicals.

- Process efficiency: Lower energy input and reduced waste.

- Sustainability: Alignment with circular economy and climate goals.

- Scalability: Proven pilot infrastructure and scale-up expertise.

TNO invites industry partners to collaborate on commercialization, licensing, and joint development opportunities. Whether you’re looking to expand your green portfolio, reduce carbon intensity, or enter new markets, this platform offers a strategic entry point.

A Call to Electrify

As renewable energy deployment accelerates globally, the chemical industry must evolve. Electrification of chemical processes is not just a technical shift—it’s a strategic imperative. TNO is committed to supporting this transition by continuously advancing electrosynthesis technologies and enabling their industrial adoption.

By partnering with TNO, stakeholders can gain early access to scalable, sustainable solutions that position them ahead of regulatory curves and market trends.

The post Electrochemistry and Biobased Furfural: A Scalable Pathway to Sustainable Chemical Production appeared first on World Bio Market Insights.