From my perch as lab manager at Greentown, I get a rare view into the daily grind of innovation: the hands-on work, the building, and—if we’re lucky—a breakthrough.

I’ve watched something unfold lately that deserves more than a passing mention. It’s a story about what happens when everything a hardware startup needs—tools, space, and critically, each other—coalesce, showcasing true creativity and potential.

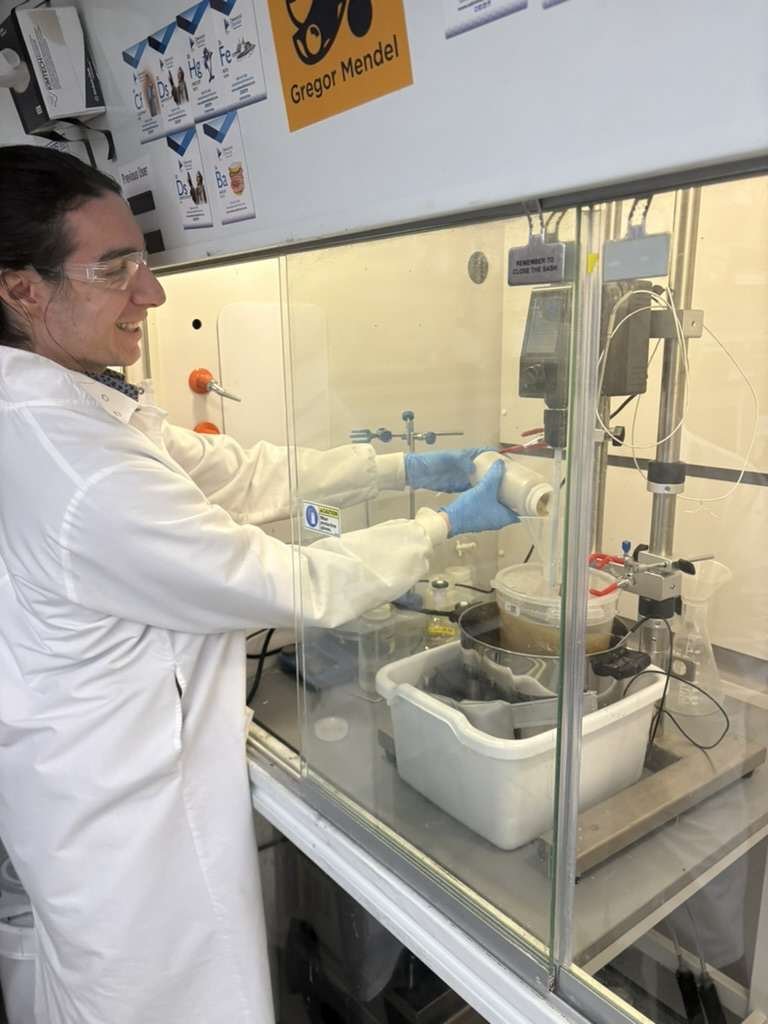

It starts with Elementium, a rising startup working on a novel liquid electrolyte for lithium-ion batteries that’s managed to launch over 30 customer trials in the past six months. Their electrolyte is unlike anything on the market, with a proprietary synthesis route that takes place entirely within our shared, BSL-2 wet lab. The Elementium team is working in our shared fume hoods, using analytical instrumentation—but it’s how they move beyond the bench that makes this so special.

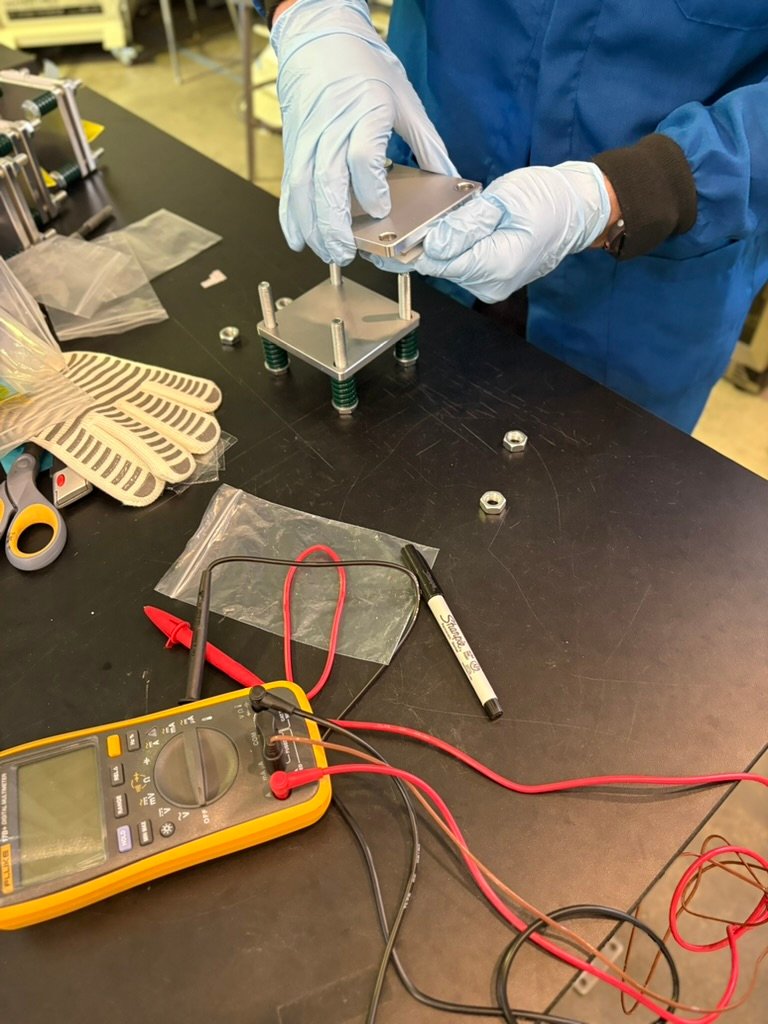

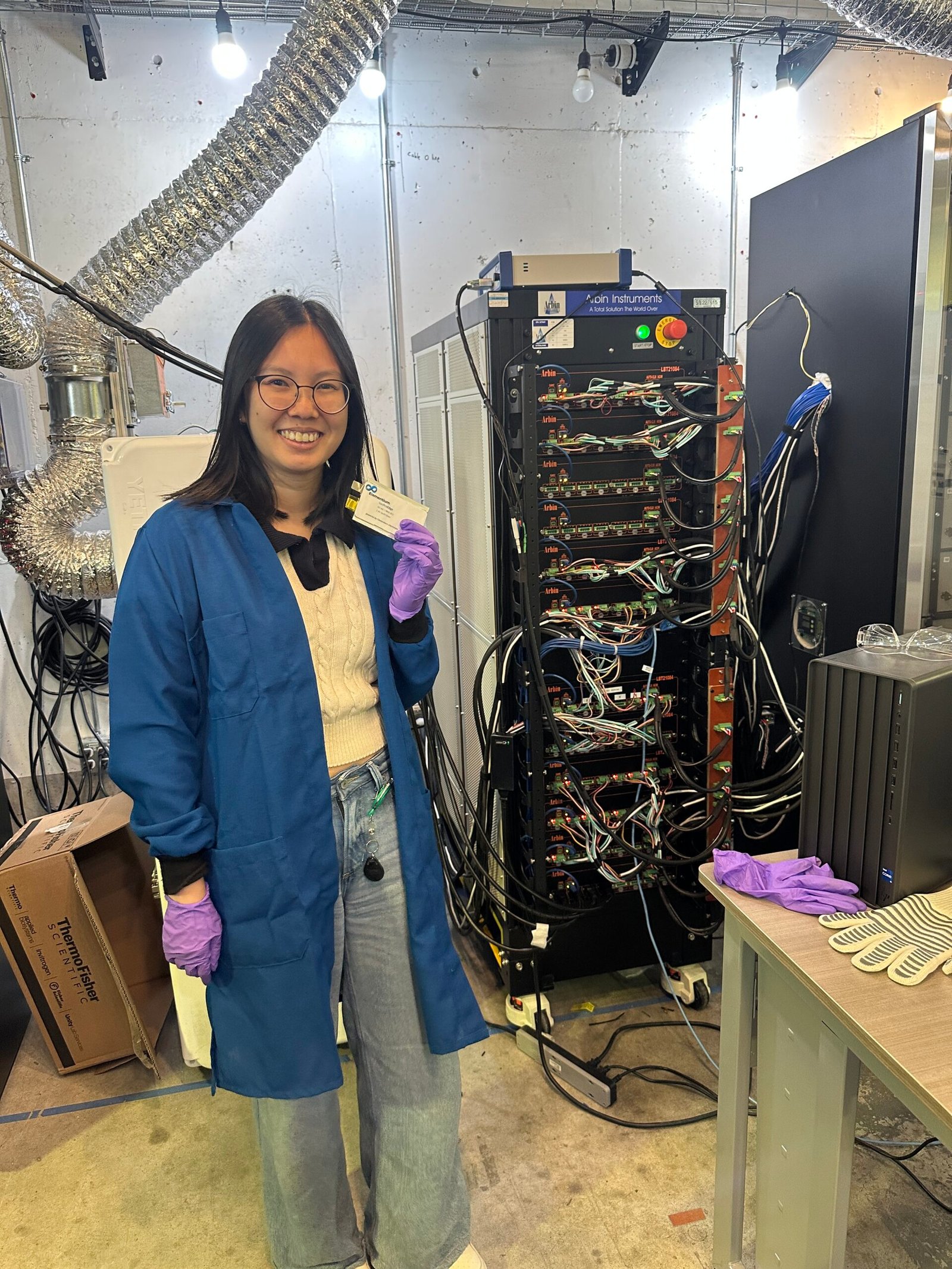

Once the electrolyte is ready, the team transitions to our prototyping lab, where they assemble pouch cells inside an argon-filled glove box. It’s a big step up from benchtop tinkering: here, there’s space and infrastructure for this kind of battery assembly and testing. Thanks to consulting from fellow Greentown member Reece Daniel and his team at Daniel Consulting Group, Elementium’s work moves faster and more confidently through these critical stages.

But the real breakthrough comes at the end of the line.

Once the cells are cycled and logged, Glimpse, another startup in the space, steps in. Glimpse runs industrial X-ray CT scans on these batteries, capturing high-resolution internal images that reveal swelling, voids, delamination, and other early failure modes before they show up in the data. It’s the kind of capability most early-stage battery companies could only dream of. But here, it’s a hallway conversation and a Slack message away.

The ability to go from electrolyte synthesis, to battery assembly, to cycling and testing, and finally to CT-based internal inspection, all without leaving Greentown and by working hand-in-hand with peers just a few feet away, is a rare and powerful thing. There’s no time lost, and specialists can focus on their specialties without awkward siloing of expertise. It’s all here. And it’s working.

As a lab manager, I often think about infrastructure: the systems, tools, rules, and data that fill up my day-to-day. But watching Elementium’s journey, what I really see is a system that truly fosters a new kind of rapid prototyping and collaboration. Our shared space and Elementium’s fellow members don’t just support their work—they amplify it.

Greg Ralich is the Vice President of Lab and Safety at Greentown. Interested in joining the Greentown community? Startups can learn about membership benefits here and apply here.

The post Only at Greentown: A Community-powered Innovation in Battery Building appeared first on Greentown Labs.