Every day, thousands of people stand along recycling lines across the country, sorting through an endless stream of bottles, cans, and debris. It’s difficult, often dangerous work and, despite their efforts, only about a third of waste products in the U.S. are recycled. The challenge has only intensified since China’s 2018 import ban on most foreign recyclables. Now, U.S. facilities are tasked with processing millions more tons of trash in complex waste streams domestically.

Glacier is harnessing artificial intelligence (AI) to tackle this growing problem. Their right-sized, affordable robotic sorters help recycling facilities recover more materials, generate new revenue, and create safer, higher-skilled jobs in the U.S.

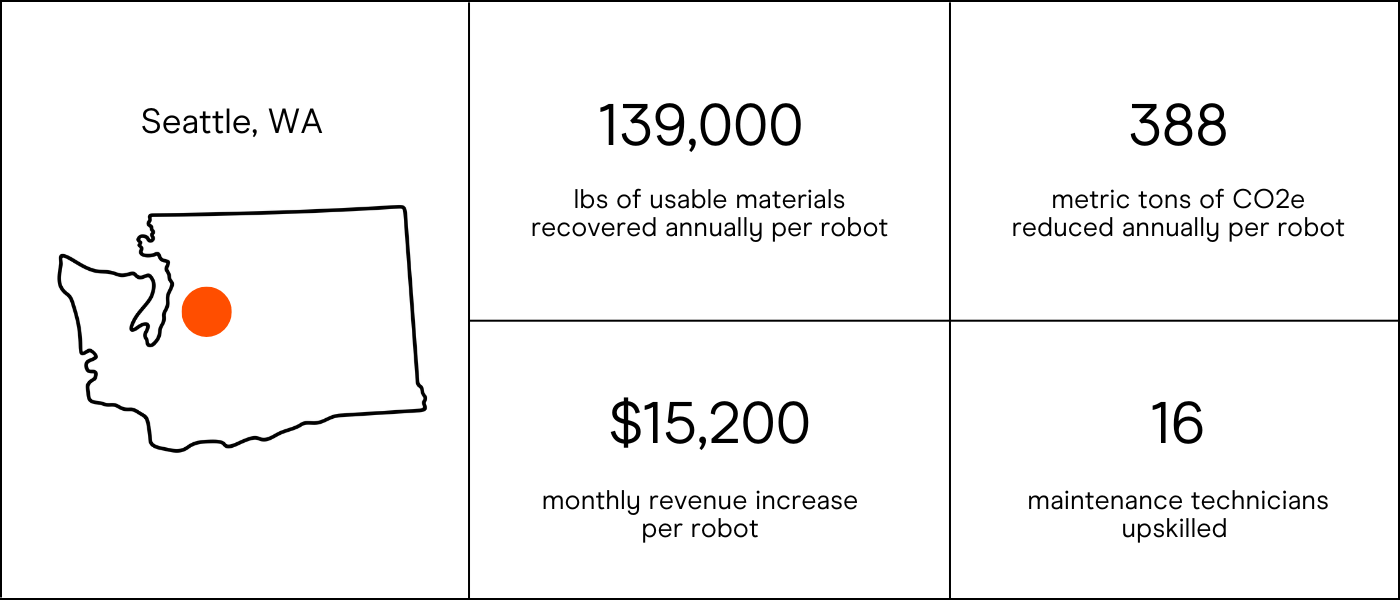

In 2025, with support from Elemental, Glacier completed its largest single-site deployment in Seattle, WA. Less than one year in, this project is already generating measurable impact:

The Opportunity: Using AI to Create Cleaner Waste Streams and Better Jobs

The U.S. recycling industry is essential to keeping communities clean and reducing waste, yet it faces mounting pressure. Material recycling facilities (MRFs) sort through everything from plastic, glass, and cardboard to garden hoses, bowling balls, and batteries of all sizes. Despite these complex waste streams, most facilities have limited visibility into what’s moving through their lines, which reduces efficiency and can be dangerous. MRFs regularly contend with fire hazards from lithium-ion batteries, resulting in tens of millions of dollars in damage and lost revenue.

At the same time, sorting work is grueling and hazardous, with injury rates twice that of the construction industry, making it hard for MRFs to fill the jobs needed to run at full capacity—many falling short of full staffing by 20% to 50% on a regular basis.*

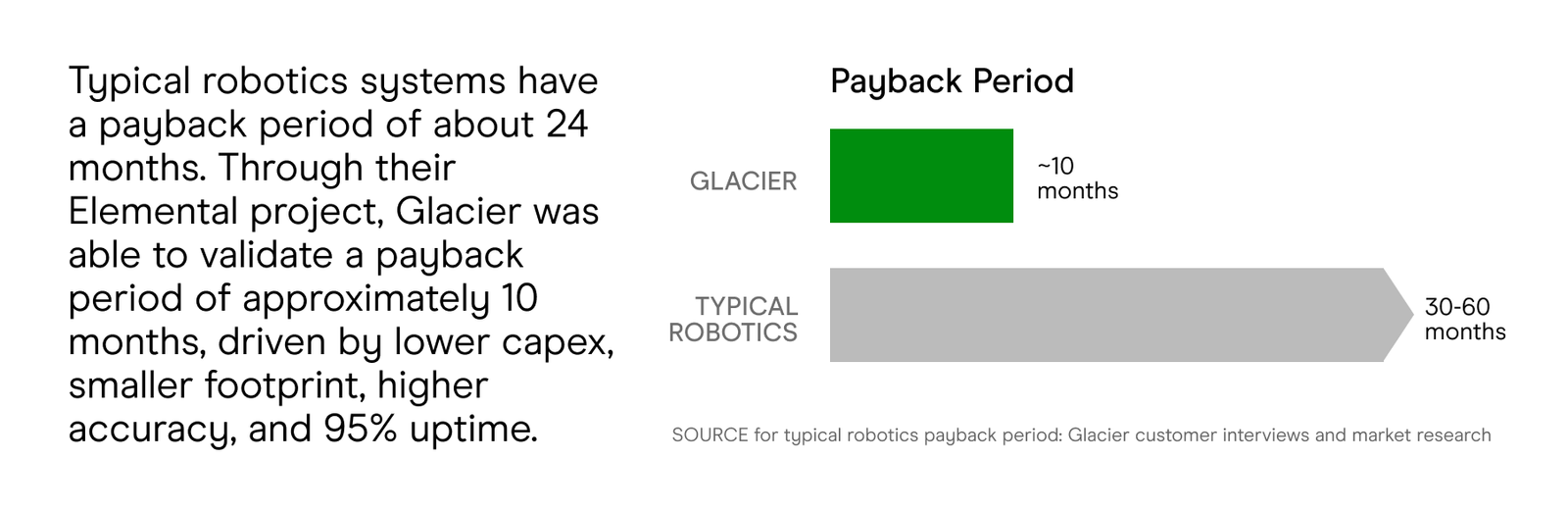

Glacier saw an opportunity to bring AI to the front lines of recycling to solve these challenges and bring the recycling industry into the age of advanced manufacturing. Their robotic sorters are compact and easy to install, using computer vision systems to sort through 70 types of recyclable materials, with human level accuracy, at a speed of up to 50 items per minute. In addition, Glacier robots use real-time analytics to provide brand and material-level insight into recovery rates, resulting in less material ending up in landfills. In the last year alone, Glacier’s robots have sorted 90 million items—rescuing more than 1,000 tons of recyclable material from the landfill and removing 48 million contaminants from the recycling waste stream. At 60% cheaper and 70% smaller than competing systems, with a zero-downtime installation, the Glacier technology is making it possible to deploy automation across a wider range of recycling facilities—from large urban facilities to small rural operations.

What also stood out to Elemental about Glacier was the fact that they don’t just deploy machines—they deeply understand the on-site needs of MRFs, and the people who power them. Co-founders Rebecca Hu-Thrams and Areeb Malik have spent thousands of hours on-site at MRFs, talking with executives, operators, and frontline sorters. One of the major insights that evolved from these conversations is that most equipment vendors don’t give MRFs the right to repair—waiting for parts and repairing equipment can result in weeks of downtime and lost revenue. By training facility staff to operate, maintain, and troubleshoot the robots themselves, Glacier is building local knowledge and ownership of the technology, while making it safer and easier for recycling facilities to adopt.

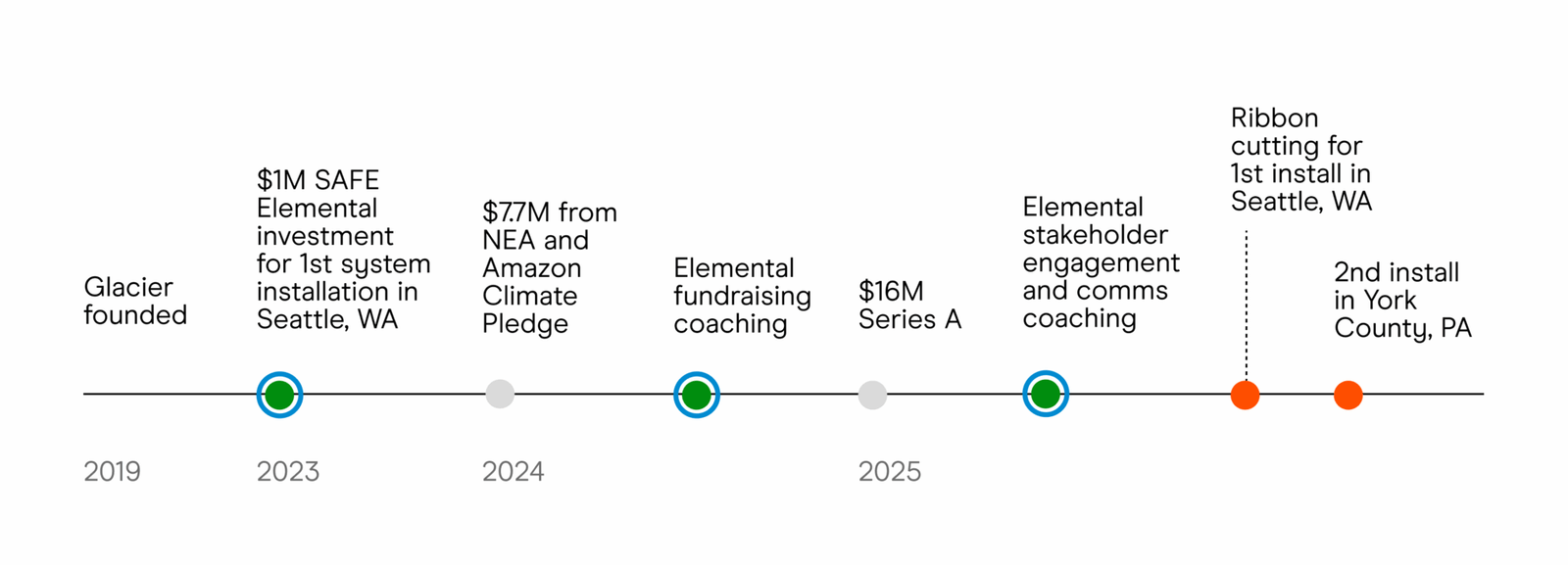

Elemental’s Investment: Driving Momentum Through Deployment

In 2023, Elemental contributed funding towards Glacier’s largest single-site deployment to date in Seattle with Recology King County (RKC). The project marked Glacier’s first end-to-end integration of its AI scanners and robotic sorters, as the team successfully deployed six AI-powered robots in several applications at the MRF. The commercial success of this project was a major contributor to Glacier’s Series A financing, led by Ecosystem Integrity Fund, with participation from notable investors including the Amazon Climate Pledge Fund and NEA.

“Having seen the success of Glacier’s technology in San Francisco, we’re thrilled to introduce it here in Seattle,” said Salvatore Coniglio, Recology CEO, about the project. “This partnership helps us ensure that more valuable materials are recovered, reducing waste and supporting a more sustainable future for everyone.”

Beyond funding, Elemental partnered with Glacier to maximize the project’s workforce impact, collaborating on a hands-on training curriculum to support the company’s right-to-repair model. Over the course of the project, Glacier designed and piloted a “train-the-trainer” program at RKC, where they led in-depth sessions for 16 maintenance technicians and managers. The program walked teams through on-site operation, troubleshooting, and preventive maintenance of Glacier’s robots—equipping workers with the skills to confidently maintain and repair the technology long after installation.

Beyond funding, Elemental partnered with Glacier to maximize the project’s workforce impact, collaborating on a hands-on training curriculum to support the company’s right-to-repair model. Over the course of the project, Glacier designed and piloted a “train-the-trainer” program at RKC, where they led in-depth sessions for 16 maintenance technicians and managers. The program walked teams through on-site operation, troubleshooting, and preventive maintenance of Glacier’s robots—equipping workers with the skills to confidently maintain and repair the technology long after installation.

We also teamed up with Glacier to co-host a public technology demonstration and ribbon-cutting ceremony for the project. Local policymakers, community leaders, industry experts, and journalists gathered at the Seattle facility to tour the MRF and view Glacier’s system in action. In preparing for and executing the ribbon-cutting, Elemental provided the following support activities:

- Worked closely with Glacier and its project partners to design and execute the event, informing the invite list to include key media, public sector officials, and prospective customers.

- Developed a communications strategy for the event and accompanying fundraising announcement, collaborated on a press release, and consulted on media strategy.

- Delivered remarks to the attendees, providing a valuable third party funder perspective on why we invested in Glacier and the opportunity of this project to deliver meaningful economic, environmental, and community benefits.

The event, which received 85+ media mentions, including local broadcast segments and coverage, was highly valuable for strengthening local relationships, highlighting Glacier’s impact, and building momentum for their next projects.

“Glacier’s partnership with Elemental has been instrumental to our most recent chapter of growth. This project has helped us to frame our work in the context of deep community impact. We have built playbooks to not only tactically deploy our technology for improved landfill diversion, but also shine a light on important dialogues between technologists, recyclers, regulators, and community groups using innovation to advance sustainability for the communities our customers serve.” – Rebecca Hu-Thrams, Glacier CEO

Scaling Up: The Road Ahead for AI-Powered Recycling

Following the success of the Seattle deployment, Glacier and Recology are expanding their partnership. Two additional robots are being installed at the RKC facility, with plans to replicate this deployment model at other Recology sites nationwide. This project also established a playbook for community engagement and workforce training, which Glacier is now using for upcoming deployments, including ribbon-cutting events with major customers in Pennsylvania and Chicago.

Building on this momentum, Glacier recently announced a landmark partnership with Waste Connections, the nation’s third-largest waste management company, and Cox Enterprises. Together, these partners are helping accelerate Glacier’s deployment of AI-powered sorters across the U.S. and validate its technology as a scalable solution for the entire recycling industry.

Glacier has now deployed dozens of robots and vision systems across more than 10 states and plans to expand to 55 full-time employees as demand grows. Their fleet of robots now processes recycling for nearly 1 in 10 Americans. The company was named to TIME’s Best Inventions of 2025, recognizing its innovative contribution to cleaner, safer, and more efficient recycling.

Looking ahead, by 2030, Glacier’s systems are expected to cumulatively divert over four million tons of recyclables from landfills and avoid 10 million tons of CO₂e every year; all while upskilling essential workers—demonstrating how innovation can not only improve recovery and operational efficiency while also strengthening communities and workforce capacity across the U.S.

_____

*Data collected by Glacier via surveys of industry operators (n≥10).

The post Smarter Machines, Safer Jobs: Glacier’s AI is Reimagining Recycling appeared first on Elemental Impact.