Tomato (Solanum lycopersicum) stands as one of the world’s most valuable and widely consumed vegetable crops, prized for its nutritional content, versatility, and economic significance.

As global demand surges and climate challenges intensify, traditional open-field cultivation faces limitations. Enter polyhouse technology: a controlled environment agriculture (CEA) system offering a transformative approach to tomato production.

Utilizing polyethylene film cladding, polyhouses create a semi-controlled microclimate, shielding crops from harsh external conditions while optimizing growth parameters. This method is rapidly gaining traction as a sustainable and profitable solution for consistent, high-quality tomato yields year-round.

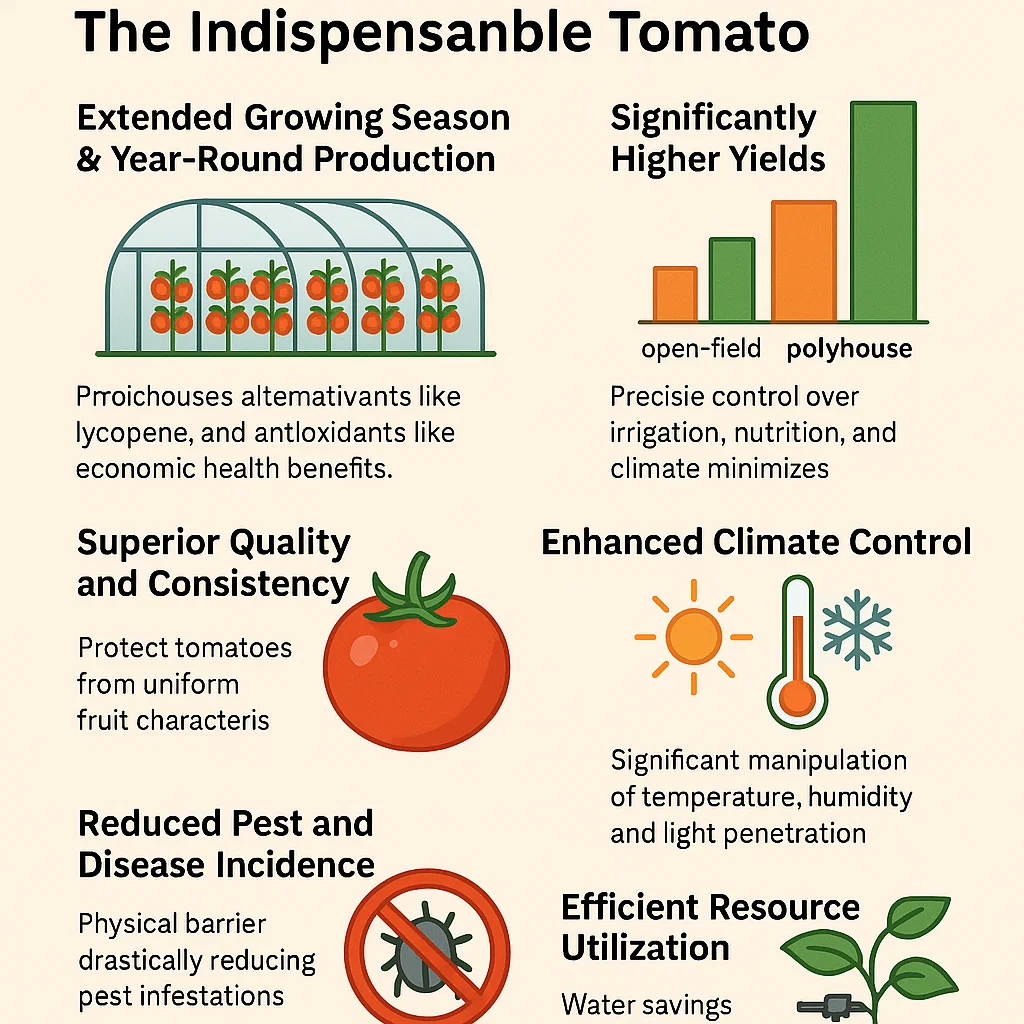

Why Grow Tomatoes in a Polyhouse? The Indispensable Tomato

Tomatoes are far more than a kitchen staple; they are a powerhouse of vitamins (A, C, K), minerals (potassium), and antioxidants like lycopene, linked to numerous health benefits. Economically, they represent a major cash crop for millions of small and large-scale farmers globally.

The global fresh tomato market was valued at over $190 billion in 2023 (Statista), underscoring its massive scale. Meeting this demand reliably, especially during off-seasons or in regions with adverse climates, requires innovative approaches beyond traditional farming.

Meanwhile, polyhouse cultivation offers distinct, measurable advantages for tomato production:

1. Extended Growing Season & Year-Round Production: Polyhouses effectively buffer against extreme temperatures, frost, and heavy rains. This allows for tomato cultivation 10-12 months of the year, even in regions with short summers or harsh winters, ensuring continuous supply and market presence.

2. Significantly Higher Yields: Precise control over irrigation, nutrition, and climate minimizes stress and optimizes growth. Polyhouse tomato yields are dramatically higher than open-field farming.

While open-field yields in India average 20-35 tons per hectare, polyhouses consistently achieve 200-400 tons per hectare annually (FAO, 2023 reports). Similar yield multipliers (3-5 times or more) are observed globally.

3. Superior Quality and Consistency: Protection from wind, rain, and direct sun reduces blemishes, cracking, and sunscald.

Controlled environments promote uniform fruit size, shape, color, and ripening. Brix levels (sugar content) and nutrient density are often higher. This translates to premium-grade produce fetching 20-50% higher market prices.

4. Enhanced Climate Control: While less precise than high-tech greenhouses, polyhouses allow significant manipulation of temperature, humidity, and light penetration (via shade nets). This protects plants from heat stress (>35°C) and cold damage (<10°C), critical for optimal tomato fruit set.

5. Reduced Pest and Disease Incidence: The physical barrier drastically reduces infestation by insects (whiteflies, aphids, fruit borers) and vectors of devastating viral diseases like Tomato Yellow Leaf Curl Virus (TYLCV) and Tomato Mosaic Virus (ToMV).

This leads to a 60-80% reduction in pesticide usage (ICAR studies), lowering costs and producing safer, more residue-free tomatoes.

6. Efficient Resource Utilization: Drip irrigation and fertigation systems within polyhouses ensure water savings of 30-50% compared to furrow irrigation in open fields. Fertilizer use efficiency also increases significantly, minimizing leaching and environmental impact.

Economic And Suitability Potential

The economic potential is substantial, though dependent on management expertise and market access. Despite moderate initial investment (₹800-1200 per sq. meter in India), the high yields and premium prices enable ROIs of 40-60% or more annually after the initial payback period (typically 2-3 years).

However, consistent supply of high-quality tomatoes during off-seasons commands significant price premiums. Polyhouse tomatoes often sell for ₹80-₹150/kg in Indian metros compared to ₹30-₹60/kg for open-field produce during glut seasons. Furthermore,

- Reduced Risk: Lower vulnerability to weather disasters and pest outbreaks provides income stability.

- Export Opportunities: Meeting stringent quality and phytosanitary standards is easier, opening doors to export markets.

- Government Support: Many governments (e.g., India’s MIDH scheme) offer subsidies of 50-65% for polyhouse construction, improving viability.

Moreover, polyhouse tomato cultivation is highly suitable for:

- Small & Marginal Farmers: Lower entry cost than high-tech greenhouses, manageable scale.

- Regions with Adverse Climates: Short seasons, excessive rain, high winds, temperature extremes.

- Urban/Peri-urban Farming: Proximity to high-value markets reduces transport costs and ensures freshness.

- Producing Premium & Off-Season Tomatoes: Catering to high-end retail, hospitality, and export markets.

Table: Production Systems Compared: Polyhouse vs. Open Field vs. Greenhouse

| Feature | Open Field Cultivation | Polyhouse Cultivation | High-Tech Greenhouse Cultivation |

|---|---|---|---|

| Climate Control | None – Fully exposed | Semi-controlled (Temp, Humidity) | Fully controlled (Temp, Hum, CO₂, Light) |

| Seasonality | Highly seasonal (4-6 months) | Extended/Year-round (10-12 months) | Year-round |

| Avg. Yield (tons/ha/yr) | 20-50 (India), 60-80 (Global Avg) | 200-400 (India/Asia), 300-500+ (Global) | 400-800+ |

| Water Use | High (Often inefficient) | Moderate (30-50% savings) | Low (Highly efficient recirc.) |

| Pest/Disease Pressure | Very High | Low-Moderate (Barrier + Control) | Very Low (Sealed Env.) |

| Pesticide Use | High | Low-Moderate | Very Low |

| Initial Investment | Low | Moderate (₹800-1200/sq.m) | Very High |

| Labor | Seasonal peaks | Consistent, skilled | Consistent, highly skilled |

| Fruit Quality | Variable, weather-dependent | High & Consistent | Very High & Uniform |

| Risk | High (Weather, Pests, Market) | Moderate (Controlled Env.) | Lower (Highest control) |

Polyhouse Structure & Setup for Tomato Cultivation

Successfully growing tomatoes within a polyhouse hinges significantly on the initial design and setup of the structure itself.

Tailoring the polyhouse environment to the specific physiological needs of tomatoes – demanding ample light, controlled temperature and humidity, and protection from pests and diseases – is paramount for maximizing yield, quality, and profitability.

Here’s a breakdown of the essential structural considerations:

1. Choosing the Right Polyhouse Type:

The selection depends heavily on your local climate, budget, and desired level of control.

1. Naturally Ventilated Polyhouses: These cost-effective structures rely on strategically placed side and roof vents (typically automated) for passive cooling and humidity control. Ideal for temperate regions or seasons with moderate temperatures.

For tomatoes, ensuring sufficient vent area (often 15-25% of the floor area) is critical to prevent heat stress and fungal diseases like Botrytis, especially during flowering and fruiting. They dominate in many developing regions due to lower initial costs.

2. Fan-Pad Cooled Polyhouses: Essential in hot, arid climates. Exhaust fans at one end pull air through evaporative cooling pads at the opposite end, significantly reducing internal temperatures (often by 10-15°F / 5-8°C).

This system provides excellent temperature control crucial for tomato pollination and fruit set during summer heatwaves. However, they increase humidity, requiring careful management to avoid disease. Energy costs for running fans and pumps are a factor.

3. Environmental Control (High-Tech) Polyhouses: Equipped with sophisticated sensors and automated systems controlling ventilation, heating, cooling (often combined fan-pad and fogging), CO2 enrichment, shading, and sometimes even supplemental lighting.

This offers the highest precision for tomato cultivation, enabling year-round production and optimizing growth parameters.

While offering the highest potential yields (often exceeding 50-70 kg/m² annually vs. 15-30 kg/m² in open field), the capital investment and operational complexity are significantly greater. Their adoption is growing rapidly in commercial operations targeting premium markets and consistent supply.

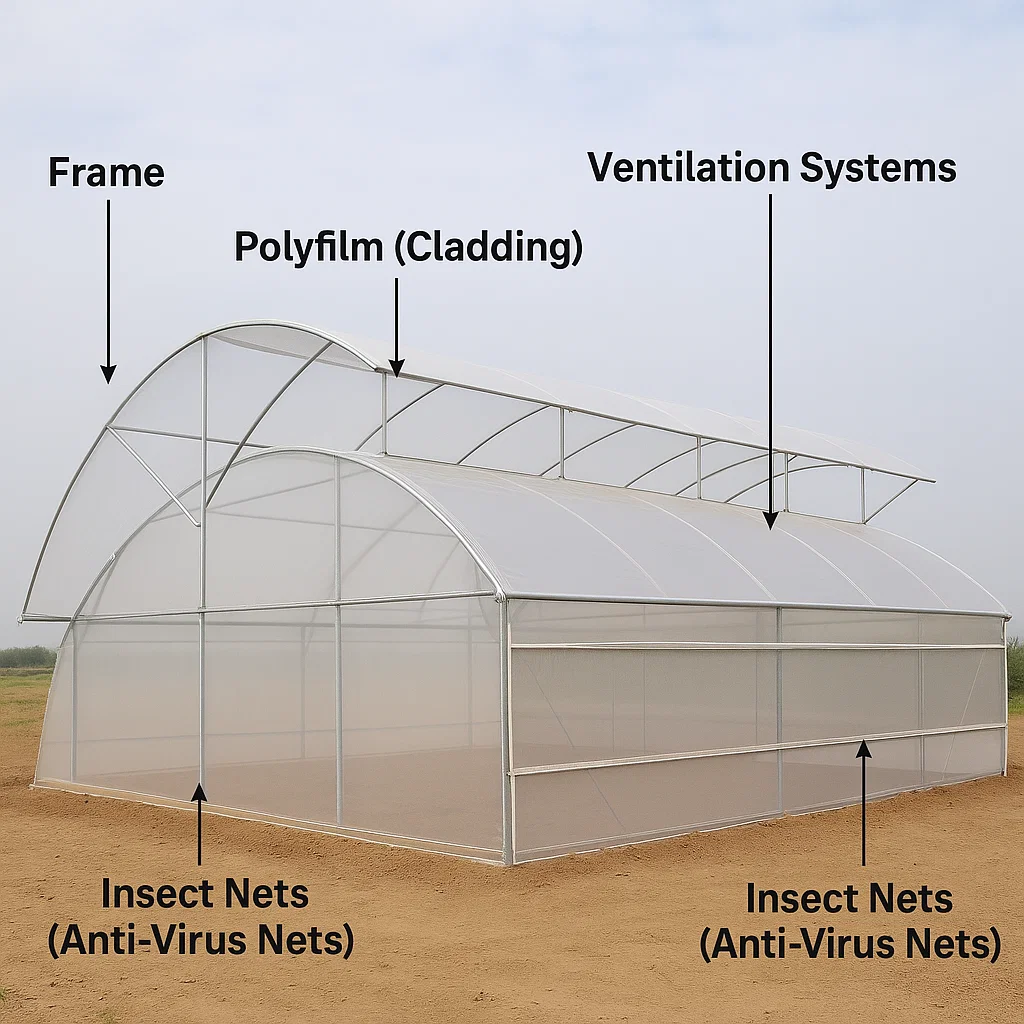

2. Essential Structure Components:

1. Frame: Galvanized Iron (GI) pipes are the standard for durability and strength to withstand wind and snow loads. Structural design must accommodate the weight of polyfilm, potential snow loads, and crop support systems (trellising for tomatoes is essential). Lifetime expectancy for a well-maintained GI frame is typically 15-25 years.

2. Polyfilm (Cladding): UV-stabilized, diffused, anti-drip films (typically 150-200 microns thick) are preferred. Diffused light reduces leaf scorch and promotes more uniform plant growth and fruit development throughout the canopy.

Anti-drip properties minimize condensation dripping onto plants, a major factor in preventing fungal and bacterial diseases like early blight and bacterial spot. Newer films incorporate NIR (Near Infrared) blocking technology to reduce excessive heat buildup. Film lifespan is usually 3-5 years.

3. Ventilation Systems: Roof vents (ridge vents) are most effective for hot air escape, while side vents facilitate horizontal airflow.

Automated vent openers, triggered by temperature sensors, are highly recommended for timely climate management crucial for tomatoes. Proper vent sizing and placement are non-negotiable for effective temperature and humidity control.

4. Insect Nets (Anti-Virus Nets): 50-mesh screens are the absolute minimum standard for physically excluding key tomato insect pests like whiteflies, thrips, and aphids. These pests are vectors for devastating tomato viruses (TYLCV, ToCV, TSWV).

Installing nets on all vents and entryways is a critical component of integrated pest management (IPM) in polyhouse tomato cultivation. Ensure proper maintenance to prevent tears.

3. Site Selection & Orientation for Optimal Light:

Tomatoes are high-light requirement crops. Therefore, site selection is critical. Choose a location completely unobstructed by buildings, tall trees, or hills, especially on the southern side (Northern Hemisphere) / northern side (Southern Hemisphere).

Tomatoes require a minimum of 6-8 hours of direct sunlight daily, with 10+ hours being optimal for maximum yield and sugar content (Brix). Furthermore,

i. Orientation: The ridge line should run East-West. This orientation ensures the longest side (typically the south side in the NH, north side in the SH) faces the sun throughout the day, maximizing light interception during the crucial winter months when sunlight intensity and duration are lower. This is vital for consistent fruit production year-round.

ii. Drainage & Wind Protection: Ensure excellent natural drainage to prevent waterlogging. While polyhouses offer protection, locating them in a relatively sheltered area from prevailing strong winds reduces structural stress and heat loss.

4. Internal Layout & Space Utilization:

Efficient use of space directly impacts productivity and operational ease:

1. Planting Beds/Bags:

Soilless cultivation (hydroponics or substrate culture) is overwhelmingly dominant in modern polyhouse tomato production (>90% in commercial setups).

Grow bags (typically 15-30 liters) filled with inert substrates like coco-peat, perlite, or rockwool are common. Raised beds lined with polyfilm and filled with substrate are also used.

This allows precise control over water, nutrients, and root zone oxygen – critical for tomato health and preventing soil-borne diseases like Fusarium and Verticillium wilt. Typical substrate volume per plant is 1.5-2.5 liters.

2. Planting Density & Arrangement:

Density depends on tomato variety (determinate vs. indeterminate), training system (single stem, V-system), and polyhouse height. Common densities range from 2.5 to 3.5 plants per square meter for vigorous indeterminate varieties.

Plants are usually arranged in double rows on raised beds or bags. Adequate spacing between plants (45-60 cm within rows) and between double rows (40-50 cm) is vital for light penetration and air circulation.

3. Aisles: Well-designed aisles (typically 80-100 cm wide for main service aisles, 50-60 cm between beds/bags) are essential for efficient labor movement, pruning, harvesting, pest scouting, and equipment access.

Wider main aisles are crucial if trolleys or small carts are used. Poor aisle design is a major bottleneck to productivity.

Therefore, investing time and resources into meticulously planning and constructing the polyhouse structure tailored for tomatoes lays the foundation for a highly productive, efficient, and sustainable cultivation system.

The right choices in type, components, location, and layout directly translate into optimized growing conditions, reduced disease pressure, lower resource waste, and ultimately, a significantly higher return on investment for the tomato grower.

Essential Growing Systems & Media For Tomato Cultivation in Polyhouses

Polyhouse cultivation offers unparalleled control over the tomato growing environment, enabling year-round production, higher yields, and superior quality compared to open fields. Central to this success is the strategic choice of growing systems and media, tailored specifically to the needs of high-value tomato crops.

1. Soil-Based Cultivation: Refining the Traditional Approach

While soilless systems gain prominence, soil-based cultivation remains relevant in polyhouses, particularly where infrastructure costs are a major constraint.

However, it demands meticulous preparation and sterilization due to the heightened risk of soil-borne diseases (like Fusarium wilt, Verticillium wilt, bacterial canker) and nematodes in the protected, intensive environment.

Modern practices emphasize soil solarization (covering moist soil with transparent plastic for 4-6 weeks during peak summer) or steam sterilization as highly effective, chemical-free methods.

Recent studies show steam sterilization achieving near-complete pathogen eradication (99%+) and significantly boosting subsequent tomato yields by 15-25% compared to untreated soil.

Amendments are crucial for optimizing soil structure, fertility, and water retention. Incorporating generous amounts of well-decomposed organic manure (25-30 tonnes/hectare) or compost, along with balanced mineral fertilizers based on soil testing, is standard.

The increasing adoption of biochar (applied at 5-10 tonnes/hectare) is notable, with research demonstrating its ability to improve soil structure, enhance water and nutrient retention, increase microbial activity, and potentially sequester carbon, leading to more robust tomato plants and yield improvements of 10-20%.

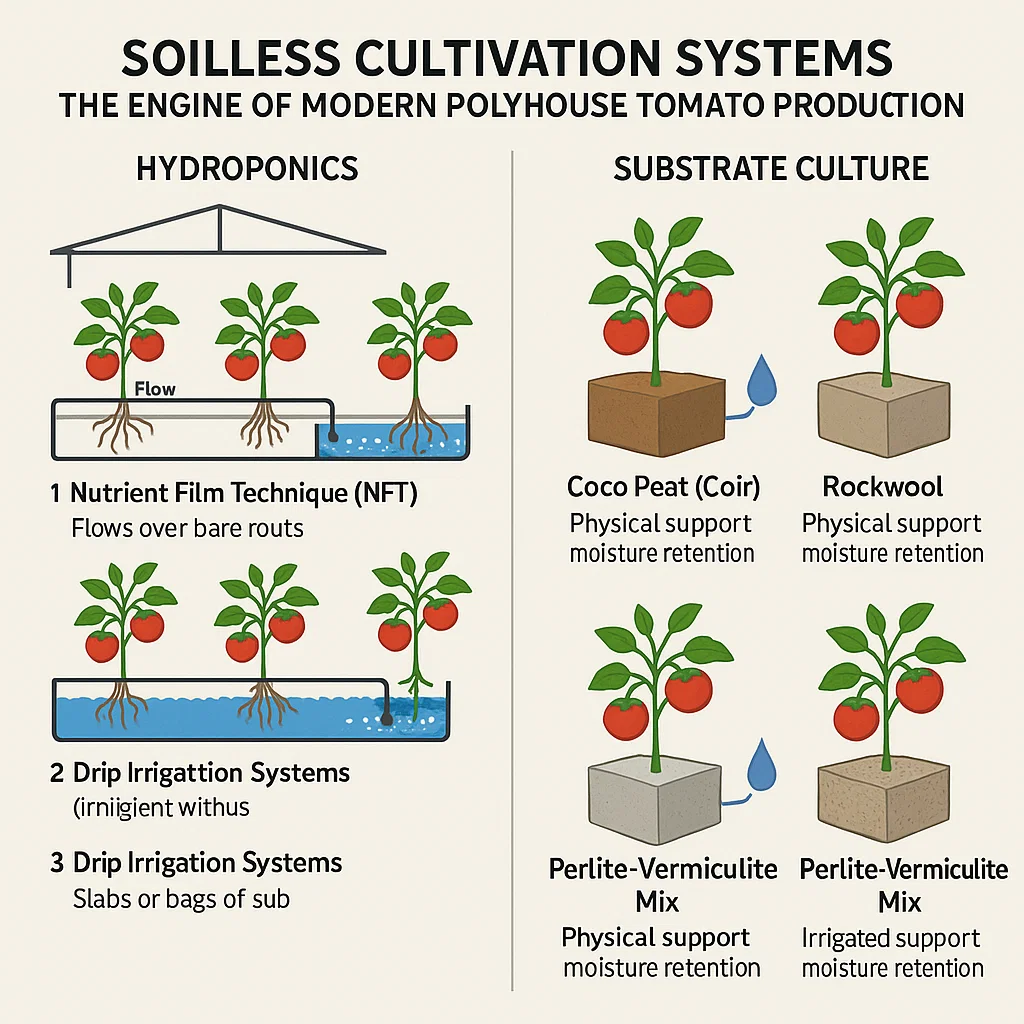

2. Soilless Cultivation Systems: The Engine of Modern Polyhouse Tomato Production

Soilless systems dominate high-tech polyhouse tomato farming globally, driven by their superior control, efficiency, disease exclusion, and significantly higher yields. They fall into two main categories:

1. Hydroponics: This method delivers nutrient-rich water directly to the roots. Key systems for tomatoes include:

i. Nutrient Film Technique (NFT): A thin film of nutrient solution continuously flows over bare roots in slightly sloped channels. While water and nutrient-efficient, NFT is less favored for large, long-season tomato varieties due to root crowding and vulnerability to pump failures. It’s more common for smaller, fast-growing crops.

ii. Deep Flow Technique (DFT) / Deep Water Culture (DWC): Plant roots are suspended in a deep, oxygenated reservoir of nutrient solution. Robust aeration is critical.

DFT offers excellent root environment stability and is increasingly used for vigorous tomato varieties, supporting yields of 40-50 kg per square meter annually in well-managed systems.

iii. Drip Irrigation Systems: The overwhelmingly dominant hydroponic method for tomatoes globally. Plants grow in inert media (like slabs or bags of substrate – see below), and nutrient solution is delivered directly to the base of each plant via drippers.

This offers precise control over water and nutrient delivery per plant, minimizes waste, and is highly scalable. Automated systems adjust irrigation based on solar radiation, stage of growth, and substrate moisture sensors.

Drip systems are the backbone of most large-scale commercial polyhouse tomato operations, enabling consistent yields exceeding 50-70 kg/m²/year in advanced setups.

2. Substrate Culture: Plants grow in solid, inert media, irrigated with nutrient solution (usually via drip). The media provides physical support, moisture retention, and root aeration. Leading choices for polyhouse tomatoes include:

i. Coco Peat (Coir): Derived from coconut husks, coco peat is the fastest-growing substrate globally (CAGR ~12.5%). Its popularity stems from excellent water retention (holding up to 8-9 times its weight), good aeration (~20-25% air-filled porosity), natural rooting hormones, and good buffering capacity.

Sustainable sourcing and pre-treatment (buffering to remove excess sodium and potassium) are key quality considerations. Coco peat slabs are the standard in many high-yielding tomato greenhouses.

ii. Rockwool: Made from molten basalt rock spun into fibers. Highly favored for its excellent water retention and aeration balance (typically 80% water, 15% fiber, 5% air when saturated), sterility, and consistent physical properties.

Rockwool slabs provide a uniform root zone, crucial for precision irrigation management. However, environmental concerns regarding disposal (non-biodegradable) are driving research into recycling options. It remains a top choice, holding a significant market share (~10.8% CAGR).

iii. Perlite-Vermiculite Mixes: Perlite (expanded volcanic glass) offers superb aeration and drainage. Vermiculite (expanded mica) provides high water and nutrient retention.

Blending them (common ratios like 70:30 or 50:50 perlite:vermiculite) creates a lightweight, customizable medium. While less common than coco or rockwool for large-scale slab production, they are popular in bag culture and for seedling production due to their sterility and ease of use.

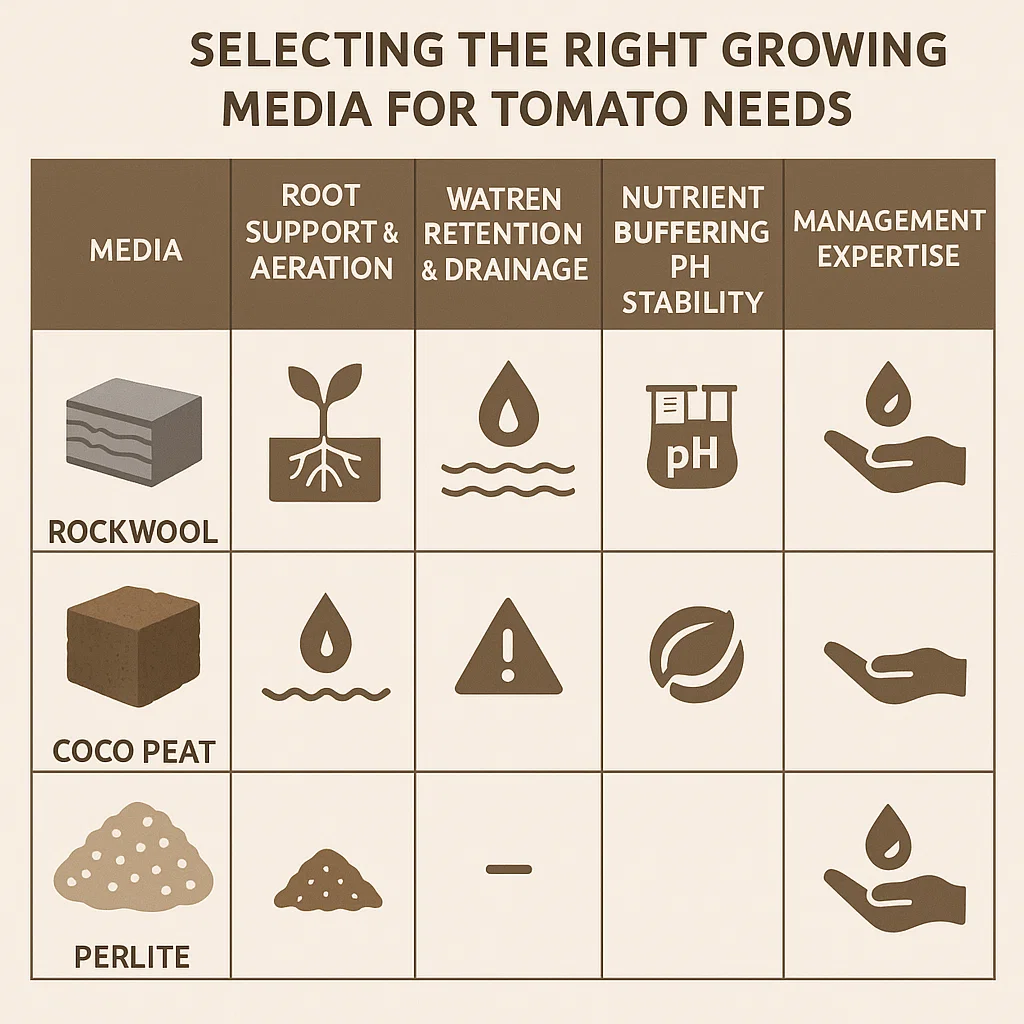

3. Selecting the Right Growing Media for Tomato Needs

The optimal media choice hinges on balancing several tomato-specific requirements and practical factors:

Root Support & Aeration: Tomatoes develop extensive root systems. The media must provide strong physical support while ensuring excellent oxygen availability (aim for >15% air-filled porosity after drainage) to prevent root rot and promote nutrient uptake. Rockwool and perlite excel here.

Water Retention & Drainage: Consistent moisture is vital, but waterlogging is fatal. The media must hold sufficient water between irrigations while allowing excess to drain freely. Coco peat offers high retention, perlite promotes drainage; blends or precise irrigation management compensate for their extremes.

Nutrient Buffering & pH Stability: Media should not interfere with nutrient availability. Coco peat requires buffering to manage K and Na levels and maintain a stable pH (ideal 5.8-6.3 for tomatoes). Rockwool is inert but has a naturally high pH, requiring pre-soaking with acidic solution.

Sustainability & Cost: Coco peat is renewable and biodegradable, but quality and consistency vary. Rockwool offers consistency but faces disposal challenges. Perlite/vermiculite are mineral-based. Initial investment, lifespan, and disposal/recycling costs significantly impact the long-term economics.

Management Expertise: Rockwool requires precise irrigation control due to low buffering. Coco peat is more forgiving. Drip systems demand technical knowledge regardless of the substrate.

Optimizing Tomato Varieties for Polyhouse Production: Choosing Your Champions

Polyhouse cultivation has revolutionized tomato farming, offering unprecedented control over environmental factors and enabling year-round production with significantly higher yields and quality compared to open fields.

In India alone, protected cultivation, including polyhouses, now covers over 70,000 hectares, with tomatoes being the dominant crop, contributing to a remarkable 22.5% share of the total vegetable production under protected structures (National Horticulture Board, 2023).

However, unlocking the full potential of a polyhouse hinges critically on selecting the right tomato variety. This decision directly impacts profitability through yield, quality, disease resilience, and market acceptability.

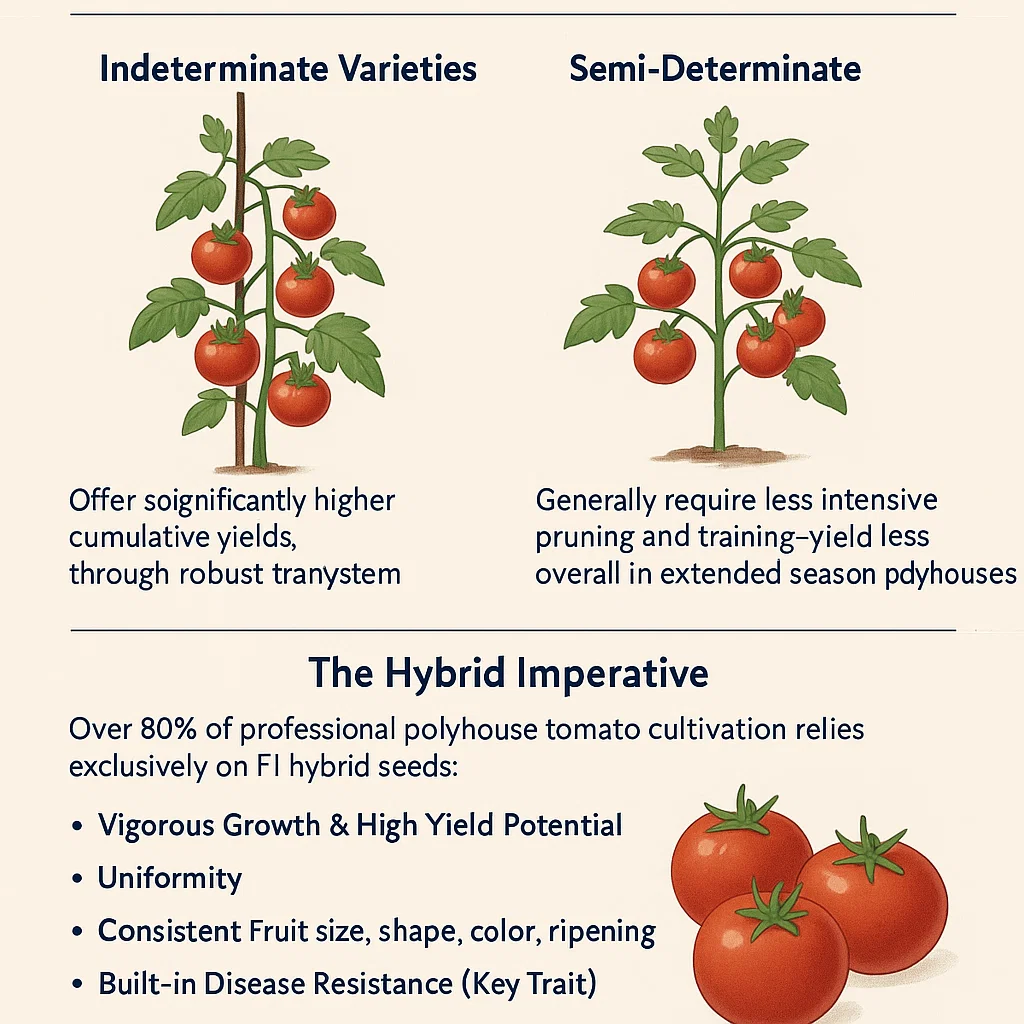

The Cultivar Conundrum: Indeterminate vs. Semi-Determinate Hybrids

The selection of appropriate tomato varieties is a critical initial step, as not all varieties are equally suited for polyhouse cultivation. For optimal results, varieties should exhibit resistance to common diseases and demonstrate the ability to thrive in controlled environments.

1. Indeterminate Varieties: The undisputed kings of long-season polyhouse production. These vines continue growing, flowering, and fruiting continuously throughout the season (often 8-10 months or more).

This characteristic leads to significantly higher cumulative yields, often reaching 60-100 kg per plant or 400-600 tonnes per hectare under optimal management.

They require robust training systems (like vertical strings or trellises) and meticulous pruning (especially side-shooting) for optimal light penetration and air circulation. Their long harvest window makes them ideal for steady supply contracts.

2. Semi-Determinate Varieties: Offer a middle ground. They grow taller than determinate types but eventually terminate their main stem growth after setting several fruit clusters. This results in a more concentrated harvest period than indeterminates, while still offering a longer harvest window than determinates.

They generally require less intensive pruning and training than indeterminates but yield less overall in extended season polyhouses. They can be suitable for shorter cropping cycles or where labor is a constraint.

3. The Hybrid Imperative: Over 80% of professional polyhouse tomato cultivation relies exclusively on F1 hybrid seeds. Hybrids deliver crucial advantages:

- Vigorous Growth & High Yield Potential: Engineered for exceptional productivity under controlled conditions.

- Uniformity: Consistent fruit size, shape, color, and ripening is vital for grading, packing, and market appeal.

- Built-in Disease Resistance (Key Trait): This is paramount in the enclosed polyhouse environment where pathogens can spread rapidly.

Modern hybrids incorporate resistance genes against devastating diseases like Tomato Leaf Curl Virus (ToLCV), Tomato Yellow Leaf Curl Virus (TYLCV), Fusarium wilt (Fol races 1, 2, 3), Verticillium wilt, Root-Knot Nematodes, Tomato Spotted Wilt Virus (TSWV), and Late Blight (Ph-2, Ph-3 genes).

Investing in resistant varieties drastically reduces pesticide use and crop loss.

Essential Traits for Polyhouse Tomato Success

When evaluating hybrid varieties, prioritize these key characteristics:

Disease Resistance: The non-negotiable foundation. Select varieties with resistance packages tailored to prevalent regional and polyhouse-specific pathogens. Check labels for codes like ToLCV, TYLCV, Fol:1,2,3, Vd, Mi, TSWV, Ph-2,3.

Yield Potential: Look for proven high yielders under protected conditions. Consider both total weight and fruit number per plant/cluster. Top-performing polyhouse hybrids consistently achieve yields 4-8 times higher than open-field varieties.

Fruit Quality:

- Size & Shape: Match market requirements (e.g., large beefsteak, medium round, cluster/truss, plum, or cherry).

- Color: Deep, uniform red (or specific hue like pink or orange for niche markets) is essential. Avoid varieties prone to blotchy ripening or green shoulders.

- Firmness: Critical for handling, transport, and shelf life. Firm fruits resist bruising and cracking.

- Brix (Soluble Solids): Higher Brix (ideally >5.0%, with many premium hybrids reaching 6.5-8.0%) signifies better flavor and sweetness, increasingly demanded by consumers and processors.

- Shelf Life: Extended post-harvest life is vital for reducing waste and reaching distant markets. Firmness, thick pericarp, and genetic makeup influence shelf life.

- Heat & Cold Tolerance: While polyhouses offer climate control, temperature extremes can still occur. Varieties with inherent tolerance to higher temperatures (reducing flower drop) or cooler periods (ensuring fruit set) provide an added buffer, especially during seasonal transitions or in regions with volatile weather.

Popular Tomato Hybrid Varieties for Polyhouses

The “best” variety constantly evolves, but several hybrids have proven successful. Specific hybrid names frequently considered for greenhouse cultivation include Inspired, Duelle, Annamay, Bountice, Bigdena, Bambelo, Nebula, Marnince, Delisher, and Climstar.

1. Large Round Beefsteak Types (Indeterminate): Namdhari’s NS-501 (ToLCV, Fol), Rasi 1288 (ToLCV, Fol, TYLCV, Nematodes), Mahyco 786 (ToLCV, Fol, TYLCV), Seminis Avinash (ToLCV, Fol, TYLCV, Nematodes), Bejo Sheetal (ToLCV, Fol, TYLCV, Nematodes, TSWV) – known for high yield, firmness, and good shelf life.

2. Medium Round/Cherry/Cluster Types (Indeterminate): Popular for fresh markets and exports. Examples include Syngenta’s Foundation (cluster, ToLCV, Fol), Rijk Zwaan’s Tricia (cluster, multi-disease resistance), Nunhems’ Savyo (cherry, high Brix, ToLCV), Arka Apeksha (cherry, high yield & TSS – IIHR).

3. High Brix & Processing Types: Hybrids like Namdhari’s NS-563 or specific plum tomato hybrids are selected for higher solids and viscosity.

4. Public Sector Gems: ICAR-IIHR’s Arka Abhed (ToLCV resistant, high yield) and Arka Abhimaan (ToLCV resistant, long shelf life) are excellent choices demonstrating significant public sector advancements.

Table: Key Tomato Varieties for Polyhouse Cultivation

| Variety Name | Type/Characteristics | Key Disease Resistance | Fruit Weight (g) | Yield (kg/m²)* | Days to Harvest (DTH) | Special Polyhouse Requirements |

|---|---|---|---|---|---|---|

| Roma | Determinate, oblong paste tomato, thick flesh | V, F1, ASC | 60-80 | 10-15 | 75-80 | Low EC nutrient solution (1.8-2.2 mS/cm) |

| Cherry Tomatoes | Indeterminate, small round fruit, high brix | TMV, F1, TYLCV | 10-20 | 15-25★ | 55-65 | High trellising (>2.5m) |

| Braveheart F1 | Indeterminate beefsteak, large firm fruit | F1, Stemphylium, Fulvia, ToMV | 200-250 | 30-40★ | 70-75 | CO₂ enrichment recommended |

| Camelia F1 | Vigorous indeterminate, cluster-type, medium round | F1, ToMV, V1, V2 | 120-150 | 25-35★ | 65-70 | Strict cluster thinning (5-6 fruits) |

| Cherry Bomb F1 | Indeterminate cherry, crack-resistant | LB: Phytophthora infestans | 15-25 | 18-28★ | 60-65 | Humidity control (<80%) |

| Chocolate Sprinkles | Indeterminate cherry, striped pattern | F, ToMV, TMV, RKN: Meloidogyne spp. | 20-30 | 12-20 | 70-75 | High light intensity needed |

| Husky Cherry Red | Dwarf indeterminate, container-friendly | ASC, F1, V | 15-25 | 8-12 | 65-70 | Suitable for low-height polyhouses |

| Jasper F1 | High-yield cherry, early maturity | EB, LB, F1, F2 | 15-20 | 20-30★ | 55-60 | Early cold tolerance |

| Lizzano F1 | Semi-determinate patio type, trailing habit | LB: Phytophthora infestans | 20-30 | 10-15 | 50-55 | Container-friendly |

| Sun Gold F1 | Indeterminate orange cherry, exceptional flavor | F1-2, ToMV, TMV, V | 8-12 | 15-25★ | 57-62 | Prone to cracking – precise irrigation |

| Super Sweet 100 F1 | Indeterminate cherry, long clusters | EB, LB, F1, TMV, V1-2 | 5-10 | 20-30★ | 65-70 | Requires frequent harvesting |

| Sweet Million F1 | Indeterminate cherry, high productivity | F1-2, Stemphylium, RKN, ToMV, TMV | 10-15 | 18-28★ | 60-65 | High Brix (7-9%) – reduce N in fruiting |

| Inspired F1 | Beefsteak, uniform size, long shelf-life | ToMV, F2, LB | 180-220 | 28-38★ | 72-78 | Sensitive to Ca deficiency |

| Duelle F1 | Cluster tomato, firm texture, transport-tolerant | TMV, F1, TYLCV | 90-120 | 22-32★ | 68-72 | EC management critical (2.5-3.0 mS/cm) |

| Nebula F1 | Round saladette, balanced flavor | V, F1, EB | 130-160 | 26-36★ | 70-75 | Moderate temperature requirements |

| Marnince F1 | Cocktail type, high brix, vibrant color | ToMV, F2 | 40-60 | 20-28★ | 63-68 | High-wind ventilation tolerance |

| Delisher F1 | Large beefsteak, juicy texture | F1, V, TMV | 200-230 | 25-35 | 75-80 | Heavy feeder – increase K during fruit |

| Climstar F1 | Heat-tolerant, continuous setting | TYLCV, F1-2, EB | 150-180 | 30-40★ | 65-70 | Heat-tolerant (>35°C) |

| Annamay F1 | Medium round, crack-resistant | LB, ToMV, V | 140-170 | 24-34★ | 70-75 | Low-light tolerant |

| Bountice F1 | High-yield round, firm fruit | F1-2, TMV, Stemphylium | 160-190 | 28-38★ | 68-73 | Requires precise Mg supplementation |

| Bigdena F1 | Extra-large beefsteak, deep red | V, F1, ToMV | 220-280 | 22-32 | 78-85 | Extended harvest period |

| Bambelo F1 | Plum type, dense flesh, low seeds | EB, LB, F1 | 80-100 | 18-26 | 70-75 | Dry matter >6% – reduce irrigation |

★ = High-yield potential varieties

DTH = Days to harvest from transplanting

Yield Estimates: Based on 8-10 month crop cycle in optimized polyhouse (varies by climate management)