Textile recycling is a massive opportunity for the whole of Europe, says the group behind an ongoing research project in Finland. Recycling technology is advancing rapidly, but a lack of regulation and challenges relating to the composition of waste materials are hindering a real breakthrough.

“In Europe alone, around 10 billion kilograms of textile waste are discarded annually. Textile fibre’s price per kilogram ranges between 2 and 3 euros, so this field offers enormous business potential,” says Ali Harlin, Research Professor at VTT Technical Research Centre of Finland.

Currently, only around one percent of the world’s textiles are recycled back into textiles. According to Harlin, the recycling challenges are primarily due to the complexity of textile raw materials and the lack of regulation.

The EU has long been working on a revision of the Waste Framework Directive, which will bring the textile sector under the so-called Producer Responsibility. As a result, textile companies themselves would be responsible for organising textile recycling.

“The EU is a global leader in textile recycling regulation, but even here, progress has been slow. Proper regulation needs to be in place before we can expect significant advancements in textile recycling rates,” Harlin says.

Recycling with the minimal processing principle

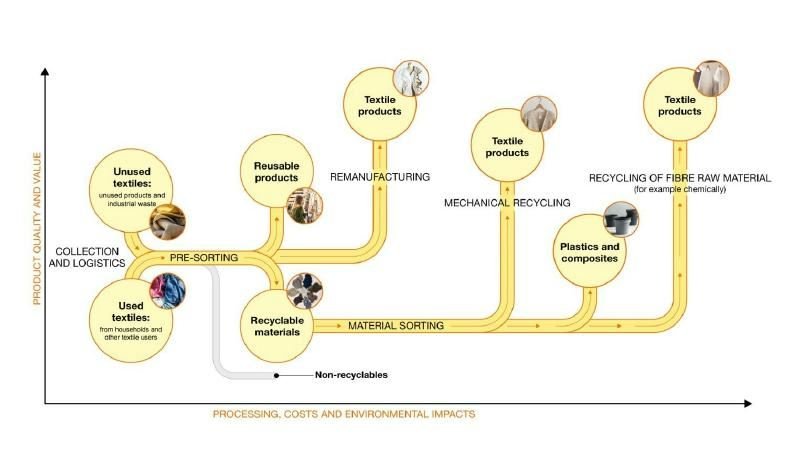

The Telaketju network of Finnish textile companies and research institutions has researched textile recycling for ten years. The Telavalue project, which ended last year, aimed to solve the sustainability and waste challenges associated with the textile industry. As VTT’s Principal Scientist Pirjo Heikkilä explains, recycling should always follow the principle of minimal processing.

“If a textile can no longer be repaired or reused, the preferred option is mechanical fibre recycling, where collected and sorted textile waste is opened by shredding the fabric and yarn structure into fibres that can be reused in textile production. When the waste is heavily worn or of low quality, it makes sense to move towards chemical recycling, where fibres are broken down and rebuilt at the polymer and even monomer level,” Heikkilä explains.

Bringing the textile industry back to Europe

According to VTT’s Ali Harlin, the increase in recycling could bring parts of the textile production chain back to Europe. Currently, strong technology development takes place in Northern and Western Europe, while manufacturing expertise is mainly based in Eastern and Southern Europe. A functioning European textile recycling ecosystem requires European cooperation.

“Individual countries are too small to act alone. Europe could see the rise of five to ten chemical recycling plants. To feed one chemical plant with textile raw material, we need approximately ten mechanical fibre plants,” Harlin calculates.

Current cotton and workwear recycling – poor quality ultra-fast fashion is a major problem

Textile recycling technology is advancing rapidly. Cotton can be successfully recycled already – a good example is Infinited Fiber Company, which is working to build a new fibre factory in Kemi, Finland. Cotton and polyester will also soon be able to be separated from each other, and chemical methods used in PET bottle recycling could be utilised in pure polyester recycling. There are dozens of suitable applications.

“Used textiles can be made into not only new textiles but also nonwoven fabrics, wind turbine blades, and even vehicle sound insulation. When textile fibre is mixed with concrete, the structure becomes lighter and more fire-resistant. In asphalt, textile fibre reduces the formation of ruts in the road,” Harlin explains.

The popularity of price-cutting, ultra-fast fashion is a major problem for textile recycling. Low-quality and mixed composition textiles are difficult to recycle profitably. The workwear sector, on the other hand, is already in a more favourable situation.

“Workwear is mainly purchased as a service, which means that the quality, maintenance, washing, and repair of the clothes are in order. Textiles are used for as long as possible, and the business model encourages the use of durable, high-quality materials. When a garment reaches the end of its lifecycle, recycling back to textiles is easier because the materials of the textiles are well known,” Heikkilä says.

According to Eetta Saarimäki, Senior Scientist at VTT, not all complex textile structures and blended materials can be recycled into new textiles. “However, through thermo-mechanical recycling, these materials can be used to produce composite products, giving them a new life one more time,” Saarimäki says.